Meet 3D MachineBuilder, a Web-Based Platform for Speeding Custom Machine Design

3D MachineBuilder from Vention is a cloud-based design and build system that could potentially speed the development time of custom industrial equipment and prototyping by five times.

August 14, 2018

|

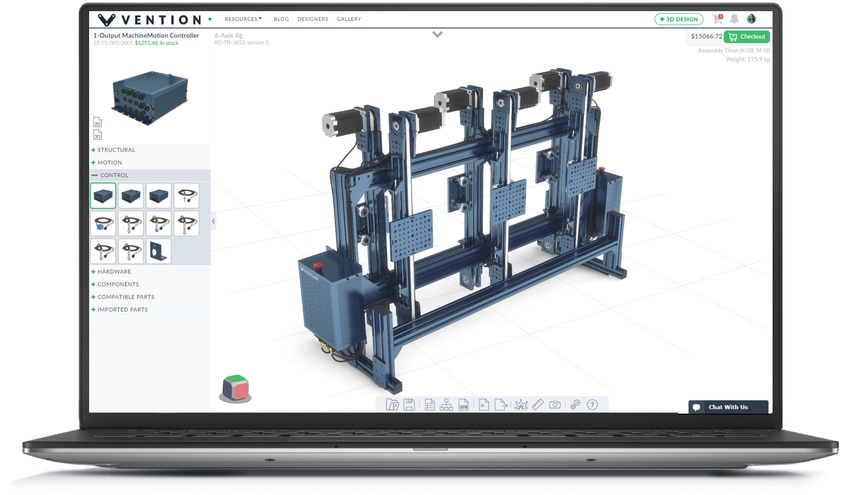

Vention 3D MachineBuilder (Image source: Vention) |

In the past, building a custom machine could be a persnickety chore rife with irritating obstacles. With a gap—sometimes a yawning gap—between hardware and software, engineers spent a lot of time comparing the specs of different manufacturers by hopping between their websites and hoping various parts would be compatible. Canadian company Vention is offering a solution in 3D MachineBuilder. This cloud-based design and build system brings hardware and software together into the same digital workflow, potentially speeding the development time of custom industrial equipment and prototyping by five times over.

The company’s public assembly library offers hundreds of open-source designs created by the company’s engineering team as well as current users. According to CEO and founder Etienne Lacroix, Vention is different because it’s the first digital manufacturing platform dedicated to machine design.

“Industrial equipment is still being designed and manufactured like it was 20 years ago, relying on a highly fragmented ecosystem of regional industrial distributors, engineering integrators, local machine shops, and desktop-based CAD,” Lacroix told Design News. “We condense this arduous process by combining a cloud-based CAD software and modular component library, allowing users to design, order, and assemble custom industrial equipment directly from a web browser in just a few days.”

RELATED ARTICLES:

There are various categories available for easy browsing, including jigs and fixtures, R&D, robotics, manufacturing equipment, material handling, industrial furniture and safety, and more. The Vention community’s public assemblies provide a starting point for engineers looking to get a jumpstart on their design projects. The platform’s public library and design tutorials are very popular with users.

It works like this: Users create their machine by accessing the parts library in Vention’s browser-based (no software or licenses necessary) 3D MachineBuilder interface to select their components and virtually assemble them. The platform also supports the import of all common CAD file formats and exports into a step file. Users designing in Vention need similar knowledge and skills required to use traditional design tools. They also have access to the Vention community to request feedback on designs, for example, or advice before buying someone else’s design. The platform leads users through the process of choosing and configuring actuators, stepper motors, and sensors.

All components have been designed to work with one another, eliminating worry about compatibility. Vention’s modular hardware is primarily designed by Vention’s engineering team, enabling the company to control all of the interface standards between all of the parts. “This ensures that parts, from framing to industrial sensors, are compatible with one another and use the same screw size,” Lacroix said. “This makes the act of assembling Vention equipment easier than assembling IKEA furniture. The foundation of our modular hardware is our patent-pending aluminum T-slot extrusions and plates. These help our users create frames around which full pieces of equipment are designed. Vention’s extrusion profile is heavy-duty in nature, providing rigidity and precision that could not be achieved with commercially available products. This specificity is the result of Vention focusing exclusively on machine design.”

When their design is finished, users review their automatically generated bill of materials and order the entire machine in a few clicks using a credit card or purchase order directly from Vention's website. Vention then prepares the order containing all the parts of the machine plus personalized assembly instructions. The order is shipped the next day as a flat-pack box and arrives ready to assemble. All components ship with color-coded and labeled wiring for easy connection. The platform includes an all-in-one MachineMotion controller designed to enable the automation of machines in minutes using open-source apps and online development tools.

|

On average, according to Vention, analysis of previous projects that used the platform found that Vention is five times faster and 40 percent cheaper than traditional workflows, which are rife with long lead times for custom parts.

The speed and cost reductions are primarily attributable to the elimination of several engineering and procurement tasks in Vention’s digital workflow. The best example is the need for 2D drawing, which is eliminated inside Vention. In addition, unpleasant surprises can be prevented, as the platform’s 3D interface provides users with accurate costs and assembly updates as they adjust their builds, allowing them to plan and budget ahead.

“For speed and ease-of-use reasons, several of Vention’s equipment pieces are based on aluminum extrusion framing,” said Lacroix. “When designing a T-slot frame, engineers need to follow similar guidelines as if they were designing it using traditional engineering software.”

The company currently serves over 20 different industries, primarily in automotive, aerospace, and robotics.

Tracey Schelmetic graduated from Fairfield University in Fairfield, Conn. and began her long career as a technology and science writer and editor at Appleton & Lange, the now-defunct medical publishing arm of Simon & Schuster. Later, as the editorial director of telecom trade journal Customer Interaction Solutions (today Customer magazine), she became a well-recognized voice in the contact center industry. Today, she is a freelance writer specializing in manufacturing and technology, telecommunications, and enterprise software.

About the Author(s)

You May Also Like