Airbus' 3D-Printed Metal Spacecraft Hinge

September 22, 2014

We've told you about 3D printed rocket engine parts and aircraft components. Now 3D-printed parts are going into space.

Using 3D printing materials and machines from Germany-based EOS, Airbus Defence and Space is making titanium brackets for telecommunications satellites. The company's Spanish subsidiary is investigating 3D printing, as well as composite materials, for use in the satellites and International Space Station components it builds.

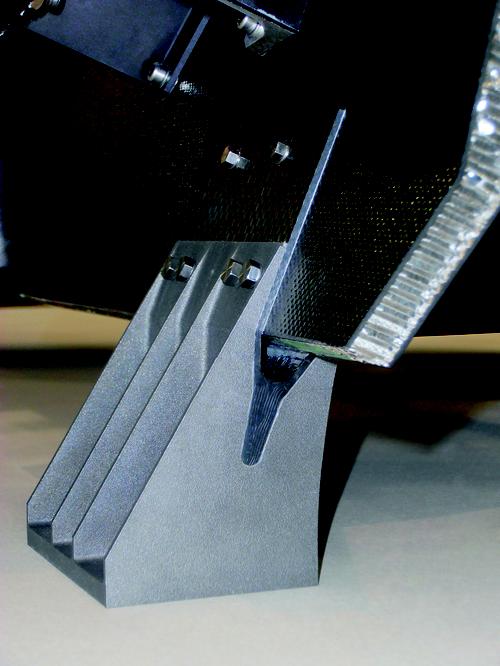

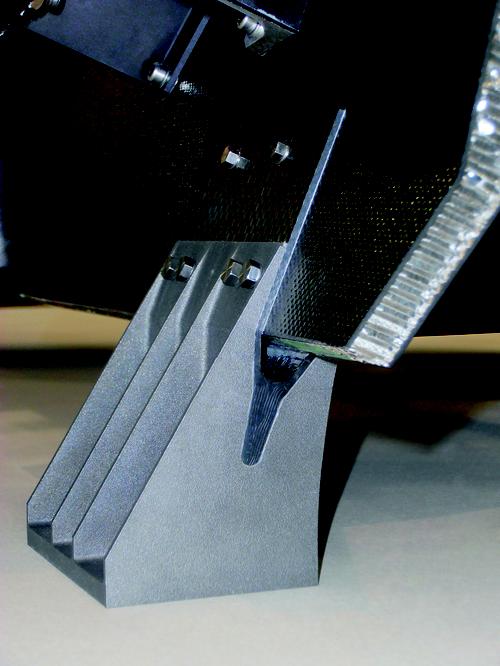

The 3D-printed brackets connect the body of the satellite to the carbon panel of the feeder facilities and reflector assembly mounted on the satellite's upper end. Three of these retaining brackets are required for each satellite -- they act as both hinges and insulation. Their material and composition must be dense enough to deliver the strength needed to securely attach the components to the spacecraft. At the same time, they must also have low enough thermal conductivity to guard against the wide range of temperatures that occur in space. Temperatures can fluctuate between -180C and 150C, which puts high stress on the hinges' material.

Titanium is often used in aerospace designs to achieve this combination, as well as being extremely lightweight. But Airbus says making these titanium brackets using traditional manufacturing methods didn't produce parts with enough resistance to thermal stress. The main advantages of using 3D printing to make them is design flexibility, which allowed an optimized redesign of the bracket to eliminate this problem. It also made possible producing the bracket in one piece, as well as cutting materials and production costs compared to traditional manufacturing methods. That became especially important because of the care it takes to install the brackets on the satellite, and the additional time, and cost, that care requires.

The 3D-printed titanium parts also have better thermal conductivity characteristics than conventionally manufactured titanium parts. The entire structure has better temperature resistance and can permanently withstand a temperature fluctuation margin of 330C under a force of 20 kN (kilonewtons). They also weigh about 300g less each, a total of almost 1 kg less for each satellite.

Using an EOSINT M 280, Airbus engineers cut the brackets' production time by five days. It now takes less than a month to produce the three brackets required for each satellite. Cost savings in production alone were more than 20%. Research was sponsored in part by the European Space Agency (ESA).

Related posts:

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)