Nano Dimension 3D Prints Production-Grade Capacitors, PCBs

Nano Dimension's DragonFly additive manufacturing system is capable of printing production-grade capacitors onto 3D-printed printed circuit boards.

September 16, 2019

|

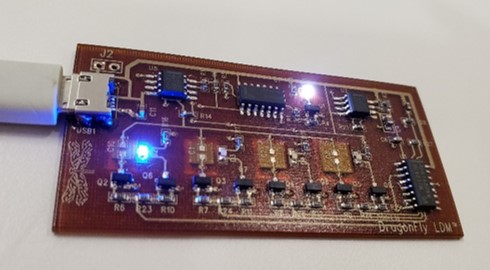

Nano Dimension says its electronics 3D printers can print production-grade capacitors directly onto 3D-printed PCBs as shown above. (Image source: Nano Dimension) |

Israeli startup Nano Dimension has announced that it has successfully used 3D printing to manufacture production-grade capacitors. Using its own DragonFly additive manufacturing system, Nano Dimension is able to 3D-print capacitors with a capacitance range from 0.1nF to 3.2nF. According to the company these capacitors showed less than 1 percent variance in over 260 repeatability tests with 30 different additively manufactured capacitors dimensions.

“The test results clearly show that with the DragonFly system our customers can achieve repeatability comparable to that of traditional processes in short run manufacturing of capacitors using 3D printing,” Amit Dror, CEO of Nano Dimension, said in a press statement. “Along with high accuracy, miniaturization, and space saving on the board, these are key factors in the electronics production process and next generation electronics applications.”

The capacitors can be embedded onto PCBs printed with the DragonFly printer as well. The system creates both the PCBs and the capacitors using the same dielectric and metal traces. According to Nano Dimension this process of printing entire capacitors and PCBs together not only saves space but also allows engineers to avoid a traditionally time-consuming assembly process.

RELATED ARTICLES:

“Additively manufacturing capacitors within the inner layers of circuits also can free space to meet the ever-increasing trend towards miniaturization and flatness of electronic devices for consumer, industrial, and military applications,” the company said. “With extra space, designers may pack more functionality on the circuit board and shrink component size - all without compromising reliability.”

Capacitors printed with the DragonFly system are primarily used for filtering electrical noise and ripple voltage and can find a home in a variety of applications including RF transmission lines, audio processing, radio reception and power circuit conditioning.

Nano Dimension bills its DragonFly system as a one-stop solution for 3D printing electronics. The DragonFly is a multimaterial injekt deposition printer that uses nano-silver and dielectric polymer ink. Earlier this year the company debuted the latest version of the DragonFly, the DragonFly Lights-Out Digital Manufacturing (LDM), a system capable of handling around-the-clock print runs – making it suitable for both prototyping and low-volume manufacturing.

Nano Dimension currently targets its printers primarily at industrial IoT applications but says it aims for its 3D-printed electronics technology to find a home in other industries such as defense and aerospace, medical devices, automotive, and consumer electronics as well.

Chris Wiltz is a Senior Editor at Design News covering emerging technologies including AI, VR/AR, blockchain, and robotics.

About the Author(s)

You May Also Like