Is 3D-Printed Food the Cuisine of the Future?

Researchers in South Korea have developed a process and printer for 3D-printing food to create custom food that is healthier for human consumption.

May 11, 2018

Researchers have 3D-printed using a wide range of materials, but so far food—aside from some limited uses—hasn’t been fully explored as one of them. Now, however, researchers in South Korea have introduced the idea of using 3D-printing technology to create food that is healthier for human consumption. Printing food at home also can minimize the waste associated with the food industry, researchers said.

Jin-Kyu Rhee, associate professor at Ewha Womans University in South Korea, led a team that built a platform that can customize and optimize how various nutrients and aspects of food are layered in food items. He presented his work—which seems the stuff of science fiction, but which researchers aim to make a widespread reality—at the annual Experimental Biology meeting in San Diego last month.

|

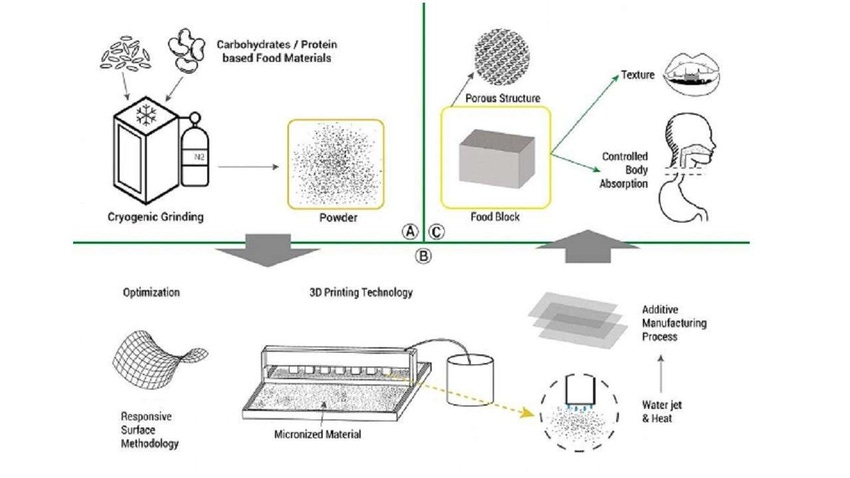

A graphic shows how food can be 3D-printed to provide people with a healthier, better-balanced diet and promote healthier eating. (Image source: Jin-Kyu Rhee, Ewha Womans University) |

“We built a platform that uses 3D printing to create food microstructures that allow food texture and body absorption to be customized on a personal level,” he said at the conference. “We think that one day, people could have cartridges that contain powdered versions of various ingredients that would be put together using 3D printing and cooked according to the user’s needs or preferences.”

While 3D-printing technology has advanced enough that people can use it to process or cook innovative foods, “food-based materials for 3D printing are still limited in terms of eating qualities, nutritional values, and functionality as well as industrial production,” Rhee wrote in an abstract about his presentation.

Rhee and his team developed a prototype 3D printer for fabricating food that has 357 nozzles. To create the “ink” for the machine, the team flash-froze various food ingredients and then ground them into a powder. The powders were then mixed with water to be sprayed through the machine and made into solids using low heat. Ingredients used included wheat protein, dextrin, and carrageenan, which is a thickening agent.

“First, carbohydrates/protein-based food materials were cryo-powdered to render…materials with characterization,” Rhee explained in the research abstract. “Subsequently, modification of structure with these micro-sized food materials has been re-crystallized by controlling water contents and heat. Then, bonding materials have been formulated and jetted onto the carbohydrates/protein-based food powders to be polymerized.”

To ensure the food looks like the real thing, the team used X-ray tomography and electron microscopy to take images of food so they could study its microscopic structure. They plan to use these images to develop software that can create 3D models of the food that the printer will use as reference for fabrication, Rhee said.

READ MORE ARTICLES ON 3D PRINTING:

Researchers also can use the science of 3D printing to create flavorful foods without sacrificing nutritional value by carefully balancing the ingredients in their cartridge combinations, Rhee said. Rhee and his team envision a future in which people print food at home that’s tailored to their own nutritional needs. They believe their technology will be especially helpful in regions where food is scarce or where the food-manufacturing industry creates a lot of waste.

The team plans to continue to work on its technology to move “3D food printing to the next level,” Rhee said. "We are continuing to optimize our 3D-print technology to create customized food materials and products that exhibit longer storage times and enhanced functionality in terms of body absorption,” he stated.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

2017 Call for Speakers INSPIRE. COLLABORATE. INNOVATE. Atlantic Design & Manufacturing, part of the largest advanced design and manufacturing industry event on the East Coast, is the annual must-attend trade show for discovering the latest in design engineering. Source from the region's most comprehensive collection of cutting-edge suppliers, deepen your expertise with free, conference-level education, and network with thousands of professionals who can help you advance your projects — and your career. From prototyping to full-scale production, one lap of the show floor will help you overcome your toughest manufacturing challenges and keep you up to speed on innovations transforming the industry. Everything you need to take projects to market faster and more cost effectively is here. Click here to register for your free pass today! |

About the Author(s)

You May Also Like