Hydrogel Shows Unprecedented Stretchability, 3D-Printing Capability

A hydrogel offering flexibility and suitability for 3D printing paves the way for new applications in medicine, soft robotics, flexible electronics, and more.

August 13, 2018

Hydrogels are hydrophilic networks of polymeric chains that can retain a large amount of water. Researchers find them useful for many applications—particularly ones that require materials that can withstand large deformations. One challenge to developing hydrogels, however, has been that traditional fabrication methods mainly rely on molding and casting. This has limited the scope of applications by geometric complexity and relatively low fabrication resolution, leading scientists to explore the 3D printing of hydrogels to improve the process—with little success so far, researchers said.

Now, a team from the Singapore University of Technology and Design (SUTD) and the Hebrew University of Jerusalem (HUJI) thinks it may have tackled this problem by developing hydrogels that can stretch in an unprecedented way. This feature opens the door for the use of hydrogels in high-resolution 3D printing to enable a range of applications in soft robotics, transparent touch panels, flexible electronics, and other areas.

|

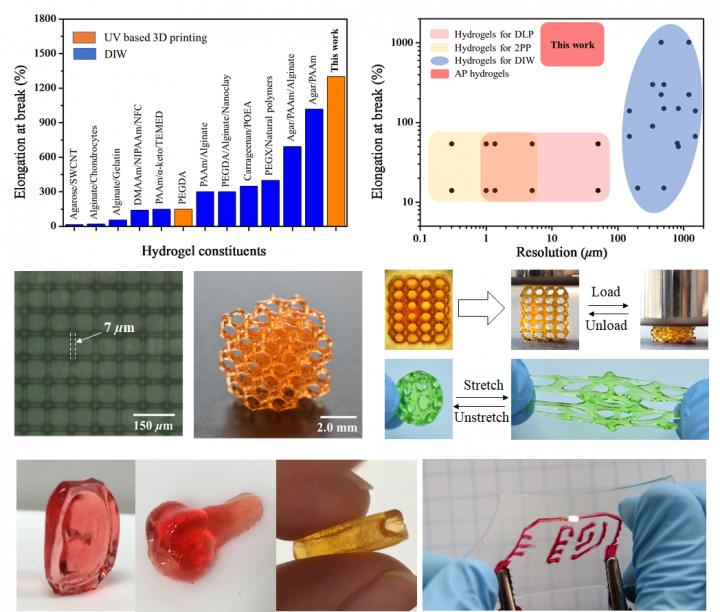

Researchers have developed highly stretchable and UV-curable 3D-printing hydrogels that can be stretched by up to 1300 percent and are compatible with high-resolution digital light processing-based 3D printing. This enables the fabrication of hydrogel structures with complex geometries that can be applied to biomedical applications and flexible electronics. (Image source: Professor Qi Ge, Singapore University of Technology and Design) |

The hydrogels developed by the researchers can be used in UV curable-based 3D-printing techniques, allowing for the fabrication of hydrogels with more complex geometries at a high printing resolution, said Assistant Professor Qi (Kevin) Ge from SUTD, one of the co-leaders of the project. "We have developed the most stretchable 3D-printed hydrogel sample in the world," he said. "The printed hydrogel sample can be stretched by up to 1,300 percent. At the same time, the compatibility of these hydrogels with digital light processing-based 3D printing technology allows us to fabricate hydrogel 3D structures with resolutions up to 7 micrometers and complex geometries."

The team’s work is a step beyond previous attempts to use 3D printing to fabricate hydrogel structures with complex geometries, including vascular networks, porous scaffolds, meniscus substitutes, and others, researchers said. Indeed, they believe hydrogels are especially well-suited to medical applications because their composition is mainly water, making them biocompatible.

Indeed, Ge said the hydrogels printed by the team “show an excellent biocompatibility, which allows us to directly 3D print biostructures and tissues.” They also possess great optical clarity, making them potentially a good fit for use in 3D-printing contact lenses, he said.

RELATED ARTICLES:

“More importantly, these 3D printable hydrogels can form strong interfacial bonding with commercial 3D printing elastomers," he added. "This allows us to directly 3D print hydrogel-elastomer hybrid structures, such as a flexible electronic board with a conductive hydrogel circuit printed on an elastomer matrix."

Researchers published a paper on their work in the Journal of Materials Chemistry B. They aim to continue their research to expand the fabrication process and application scope for which the hydrogels can be used.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

|

About the Author(s)

You May Also Like