Free E-Book: 3D Printing with Metals for Design Engineers, Explained

Metal 3D printing is getting real. In this free e-book, we've gathered some guidelines for engineers on designing for 3D metals printing and how it differs both from traditional metals techniques like casting, as well as 3D printing with polymers.

October 10, 2018

|

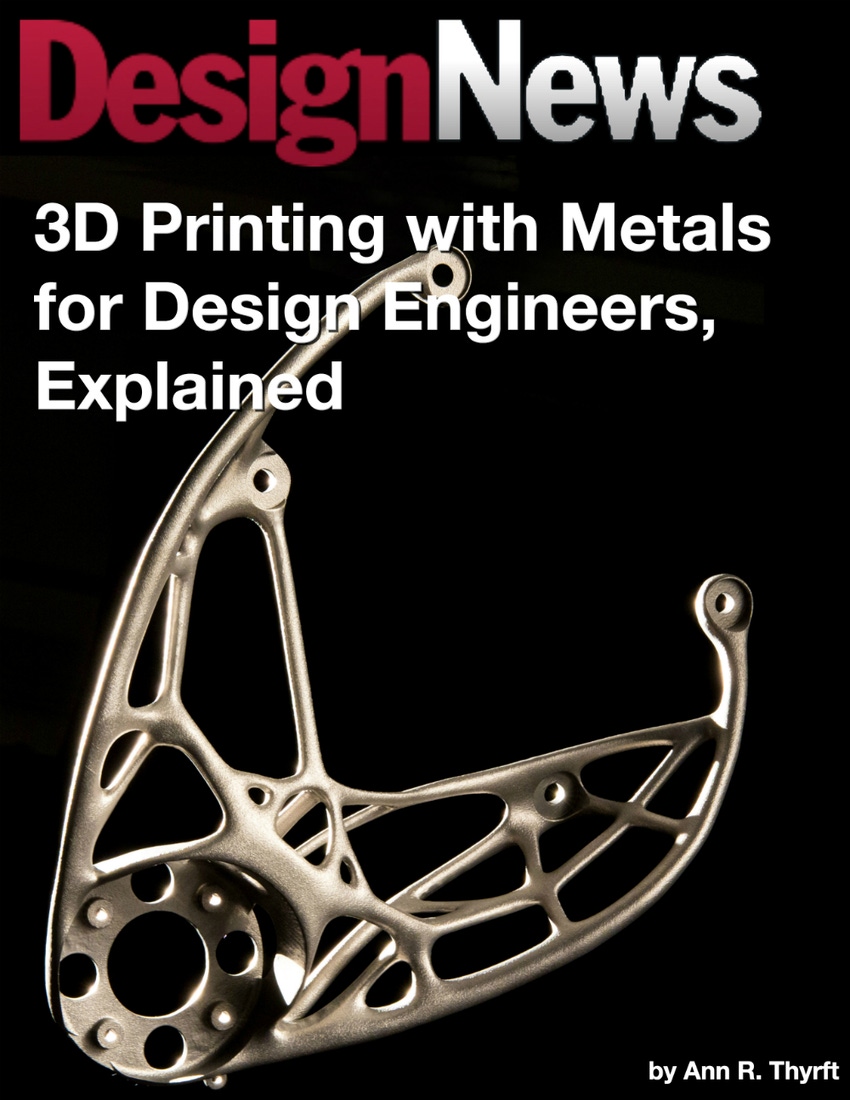

(Image source: 3D Systems) |

The use of metals in 3D printing for industrial series production is becoming more common—and not only for aerospace, biomedical, and automotive uses. Those are still the leading industrial application sectors, but they're not alone anymore in this alternative to traditional metal fabrication for end-use parts.

The use of metals additive manufacturing (AM) rose dramatically last year, as measured by the number of machines sold: 80% more in 2017 than 2016, according to the 2018 edition of the industry's venerable Wohlers Report.

A recent study by the Society for Manufacturing Engineers (SME) concluded that the exponential growth in metals AM is resulting in job growth and demand for industrial AM application and design engineers. The study, released at this year's RAPID + TCT show, also found growing demand for the following: mechanical and materials engineers with specialized backgrounds in industrial AM processes and materials science; quality engineers with AM expertise; and manufacturing engineers who can think differently about the changes that AM brings to deployment and supply chain logistics.

At least in part, the SME says the rising interest in metals AM is due to better process monitoring and quality assurance, as well as a continuing gradual decline in the average cost per machine caused by the growing availability of smaller desktop printers. Many more metals designed for AM are also available, says the report—especially for powder bed fusion, the most widely used process. Other metals AM processes for manufacturing are binder jetting, material jetting, and material extrusion. Additional factors contributing to the rise in metals AM include faster printing by machines equipped with multiple lasers and better software for optimization of complex designs and for printing lighter, stronger parts. Yet challenges remain, including the continual need for speed improvements—especially when printing large parts.

Standards are advancing, too. The roadmap published last year by the Additive Manufacturing Standardization Collaborative (AMSC) identifies which standards already exist and which are in development. It also identifies where there are gaps—including several for metals AM—and recommends areas that are top priorities for developing more standards. The AMSC was formed in 2016 as a collaboration between America Makes and the American National Standards Organization (ANSI), and now includes multiple standards development organizations, such as ASTM International, the American Society of Mechanical Engineers (ASME), and SAE International.

Additive manufacturing for end-production is complex. Using metals AM for end-production is even more complex, and can be confusing to anyone that's new to the topic. In this special e-book, we've gathered some guidelines for engineers on designing for 3D metals printing, and how it differs both from traditional metals techniques like casting as well as 3D printing with polymers. We've also included some advice on integrating this non-traditional manufacturing method into a company's culture.

Click below to download the full e-book.

Ann R. Thryft has been writing about manufacturing- and electronics-related technologies for 30 years, covering manufacturing materials & processes, robotics, single-board computers, machine vision, embedded devices, and all kinds of datacom and telecom.

About the Author(s)

You May Also Like