Ceramics Offer Amazing Diversity for 3D Printing

3D-printed ceramics offer many industries a range of applications not found in many other materials.

June 28, 2019

|

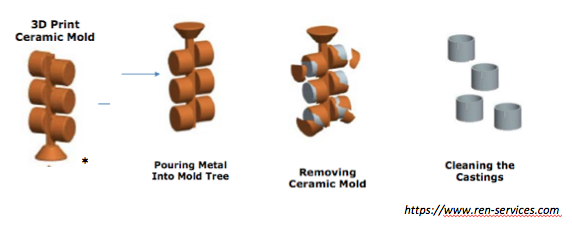

Ceramic 3D printing can pose a number of advantages such as simplifying the process of traditional investment casting. (Image source: Ren Services) |

We talk a lot about what’s going on with metal powders and resins and the advances in thermoplastics that are adding a whole new level of functionality to FDM printers. However ceramics are coming to occupy their own niche within additive manufacturing. By now you're probably thinking, why focus on yet another 3D printing material? The answer is because 3D-printable ceramics offer a range in technologies and applications not found in many other areas of 3D printing.

3D printing with ceramics deserves a shoutout for a number of reasons: It has unique material properties making it applicable to a wide variety of fields; those properties allow for a design freedom unique even by the standard of additive manufacturing; that design freedom allows for creating complex geometries that would be tricky, if not impossible, in other materials and certainly impossible with any traditional manufacturing technologies; these unique qualities lead to diverse applications and a wonderfully low-to-zero material waste ratio. Finally, ceramics can be used across a surprising variety of AM technologies.

Ceramic materials can be put into a paste form so they can actually be used in an extruder very much like the FDM process. However you can also get 3D ceramic filament in a powder form to be used in powder sintering technologies like SLS. However, ceramic powders are also available in a form compatible with binder jetting. It's also possible to get resins with ceramic particles embedded in them, making it possible to use photopolymerization technologies with ceramic elements.

Industrial vs. Desktop Ceramic

There are two categories of ceramic 3D printers: industrial and desktop. On the industrial side the prices vary widely but you can get industrial quality 3D printers for as low as $25,000.

A List of 3D-Printable Ceramic Materials |

|

However, most of them range well above that into the $100,000 or $250,000 mark. These printers span the spectrum of AM technologies from FDM and resin to powder based. I always recommend to the companies I work with if you're looking to bring any industrial 3D printer in house – regardless of the material or technology – work with a manufacturer who will also print parts. The value of working with the service bureau arm of a 3D printer manufacturer is that you can order parts and test them to make sure that their particular technology and material is right for your application.

These materials are available from a variety of 3D-printed ceramic service providers, but some of the better known ones are Lithoz, 3D Ceram, Admatec, i.Materialize, and Shapeways. These companies represent an enormous body of knowledge about what materials and what applications are best for 3D-printed ceramics.

However, you don't have to go industrial size. There are a range of desktop-size 3D-printed ceramic machines that range in price from anywhere from $5,000 to $10,000. Some of the better known ones include 3D Potterbot 7, Bison 1000, and Lutum.

3D-Printed Ceramics for Healthcare and Beyond

But whether you are using an industrial 3D printer or a desktop 3D printer, the applications for 3D-printed ceramics are remarkably broad. NYU Langone recently completed a study in which 3D-printed ceramic lattices were used to successfully guide the regrowth of new bone in patients with bone deformations.

In the NYU researchers' process, a 3D printed ceramic lattice structure is implanted into the body and then bone grows over the lattice structure in the correct orientation of what the bone should be. Clinical trials for this are still years away, but the promise and potential are extraordinary.

It's All About the Thermal Properties

The well-known thermal properties of ceramic, combined with the geometries 3D printing makes possible, open up a new range of possibilities. One of the areas where this can substantial impact is in traditional investment castings. Ceramic filaments used in an additive manufacturing process can reduce the time and cost of investment castings drastically.

For example the traditional process of creating an investment casting typically goes something like this: You machine a die, inject the die with wax, assemble a wax mold tree, coat the wax mold tree with a slurry, then given that tree a ceramic coating, melt out the wax, fire the ceramic, and finally pour in the molten metal, chipping away the ceramic mold so that you are left with your castings. This last step is particularly time consuming and costly.

However, with a ceramic filament it is possible to simply 3D print the mold in the first place (rather than starting with machining a die), do the firing process, and go right to pouring in the metal, remove the ceramic, and then work directly with your castings. Using an additive technology can take your process can from 10 steps to four and quite literally reduce the time and cost by 60, 70, even 80 percent. This has enormous implications for the feasibility of replacing broken parts on old legacy equipment that would be too costly to manufacture otherwise.

The two use cases discussed here don’t even qualify as the tip of the tip of the iceberg for what’s possible with 3D printing ceramics. Few materials are as adaptable to multiple AM technologies (FDM, SLA, binder jetting, and laser sintering) as ceramic. And as design engineers continue to push the envelope with what’s possible we will see novel applications in healthcare, aerospace, space flight, and many other areas.

Jack Heslin is the Founder of 3DTechTalks, an additive manufacturing consulting firm helping companies determine the correct Additive process and materials for their environment. He is also Head of Business Development for Lazarus3D, a medical 3D printing company providing soft tissue anatomical models for pre-operative planning and medical device simulation.

Drive World with ESC Launches in Silicon Valley This summer (August 27-29), Drive World Conference & Expo launches in Silicon Valley with North America's largest embedded systems event, Embedded Systems Conference (ESC). The inaugural three-day showcase brings together the brightest minds across the automotive electronics and embedded systems industries who are looking to shape the technology of tomorrow. |

About the Author(s)

You May Also Like