3D-Printed Ceramic Bones Grow Faster with Turmeric

Researchers have found that a compound found in turmeric can help improve the growth of 3D-printed ceramic bone scaffolds.

May 23, 2018

Nutritionists and health-food proponents have long known about the health benefits of turmeric. Now, scientists are beginning to see how the spice can help improve the bone-growing capabilities of 3D-printed bones.

A team at Washington State University (WSU) has combined aspects of natural medical cures with modern biomedical techniques by pairing curcumin—a compound found in turmeric—with ceramic bone scaffolds. Their aim is to improve the capabilities of artificial bones to grow in a way that can benefit people who suffer from bone injuries or diseases like osteoporosis.

|

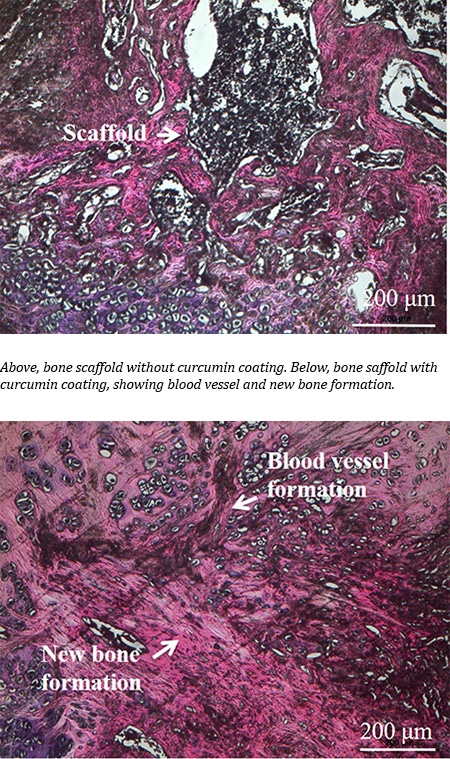

The image above shows a 3D-printed ceramic bone scaffolding without the use of a curcumin coating. In contrast, the one below shows one that was coated in curcumin and already demonstrates blood vessel and bone growth. Researchers at Washington State University (WSU) developed a process to use curcumin this way to improve outcomes for people with bone diseases. (Image source: WSU) |

Asian countries have been using turmeric as medicine for centuries. Curcumin has been shown to have antioxidant, anti-inflammatory, and bone-building capabilities, as well as success in preventing various forms of cancers. However, the human body doesn’t absorb curcumin well when it’s taken orally, as the compound becomes metabolized and eliminated too quickly.

The WSU team—led by Susmita Bose, chair professor in the School of Mechanical and Materials Engineering—found that by coating 3D-printed, ceramic bone scaffolds with curcumin, they could improve their ability to grow bones by 30 to 45 percent. Those bone scaffolds are composed of about 68 percent calcium phosphate.

“3D-printed calcium-phosphate-based bone-like scaffolds can be made patient-specific and/or defect-specific based on the patients' need,” she told Design News. “Different natural medicinal compounds can be used in them or on bone-like, material-coated metal implants for load-bearing sites to enhance bone growth inside and around the implants.”

Timing the Release

Specifically, the researchers encased the curcumin within a hydrophilicpolymer, using a large molecule so that it could be gradually released from their ceramic scaffolds. In addition to accelerating the bone’s healing process, the curcumin increased the viability and proliferation of new bone cells and blood vessels in surrounding tissue.

Bones in the human body continue to form and remodel themselves throughout our lives. However, as we age, this cycle doesn’t work as well, with bones becoming weaker. Bone diseases like osteoporosis of course make this worse, damaging and destroying bones over time.

Current medicines used for osteoporosis work by slowing down or stopping the destruction of old bone or by forming new bone. However, while they may increase bone density, they also can create an imbalance in the natural bone-remodeling cycle. They may actually create bones with poorer quality, researchers noted.

Bose said she sought a more natural way to improve bone health from the perspective of her profession as well as her own health and the health of her children. “It is one of my hobbies to learn about natural medicinal compounds,” she told us. “Certainly, as a mother, I also wanted to look at some of the home remedies for the family. As a scientist, I wanted to combine the thoughts of natural medicinal compounds with modern technology.”

RELATED ARTICLES:

Researchers believe their work is an important breakthrough to help develop new medicines that can naturally create better bone without affecting the natural bone-remodeling cycle, Bose said.

“The ceramic scaffolds can be primarily used for bone defects, at the low load-bearing sites, depending on the size of the defects,” she explained. “We are also using these natural medicinal compounds on bone-like, material-coated metal implants for load-bearing sites in our body, such as hip or knee implants. We use bone-like calcium phosphate ceramic materials, something that can dissolve in our body with time as the tissue grows inside it.”

Evaluating More Compounds

Bose and her team plan to continue their work with further study for a better understanding of exactly how the natural compound works, she said. Meanwhile, researchers also are investigating how compounds from aloe vera, saffron, Vitamin D, garlic, oregano, and ginger can inform their work.

“We are trying to enhance the bioavailability of these natural medicinal compounds and optimize delivery-vehicle chemistry to control the release kinetics of medicinal compounds,” Bose explained. “We are also looking at what protein expression and bone cell material interactions can be enhanced as well as response in the small animal model.”

Elizabeth Montalbano is a freelance writer who has written about technology and culture for 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

2017 Call for Speakers INSPIRE. COLLABORATE. INNOVATE. Atlantic Design & Manufacturing, part of the largest advanced design and manufacturing industry event on the East Coast, is the annual must-attend trade show for discovering the latest in design engineering. Source from the region's most comprehensive collection of cutting-edge suppliers, deepen your expertise with free, conference-level education, and network with thousands of professionals who can help you advance your projects — and your career. From prototyping to full-scale production, one lap of the show floor will help you overcome your toughest manufacturing challenges and keep you up to speed on innovations transforming the industry. Everything you need to take projects to market faster and more cost effectively is here. Click here to register for your free pass today! |

About the Author(s)

You May Also Like