American Cleaning Institute (Washington, D.C) members’ path to packaging sustainability relies on optimizing plastics, addressing key challenges and piloting reusable containers via Loop.

December 12, 2019

Improving sustainability in packaging is challenging enough for food and beverage products, for example, but the goals and options to do likewise for cleaning products is more complicated.

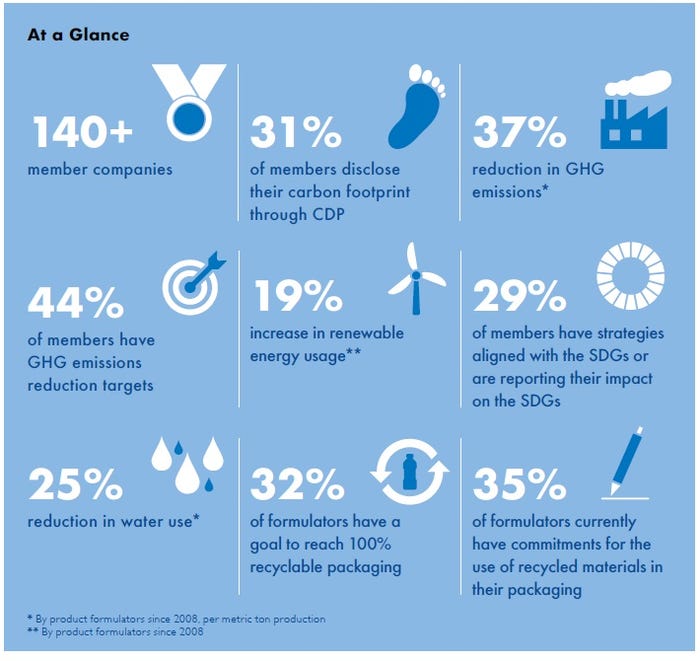

However, a pathway to improved sustainability has been formulated by the American Cleaning Institute (Washington, D.C), which called into action more than 140 members in September with the release of the organization’s 2019 Sustainability Report. The report detailed a new strategy calling on the cleaning products industry to take bolder, collective action to achieve a cleaner world. ACI’s strategy aims to unite industry efforts for greater impact across four critical goals:

Increase Transparency;

Reduce Emissions;

Value Nature;

Contribute Positively.

“We’re pushing our members to think bigger, be fearless and implement ever-more innovative solutions,” says Melissa Hockstad, ACI President and CEO. “Our new strategy combines our core strength of collaboration with a commitment to doing our part as an industry to address the sustainability challenges facing our globe.”

ACI’s 2019 Sustainability Report details these new goals and how members are already taking action, for example:

Helping consumers choose products that are best for them by sharing more information about their products and practices through digital means;

Joining global alliances to clean up our world and limit plastic waste;

Utilizing new circular approaches to packaging and simplifying the consumer experience;

Managing and reducing the use of hazardous chemicals through approaches like chemical footprinting;

Setting operational greenhouse gas (GHG) emission reduction targets that support the Paris Agreement; 44% of ACI members have set targets to reduce GHG emissions and in 2018, 54% of ACI members reported GHG emissions results while their renewable energy use increased 19%.

PlasticsToday connected with Melissa Grande, ACI’s Director, Sustainability, to learn more about the market, the packaging and the plans, starting with what is meant by digital.

PlasticsToday connected with Melissa Grande, ACI’s Director, Sustainability, to learn more about the market, the packaging and the plans, starting with what is meant by digital.

“We understand that it can be difficult to identify and comprehend the varying types of information available for products found on store shelves today,” explains Grande. “For instance, SmartLabel makes it easier for consumers to have detailed information on thousands of products at the press of a button, in a uniform and consistent way across brands.

“The app works with any smart device and contains far more information than could fit on package labels. Simply by scanning the QR code on the product, people can access useful product and ingredient information to help them make informed choices about what they buy. At time of report publishing, 30% of ACI household product formulators use SmartLabel, and more are expected to join in the coming months.”

And what about chemical footprinting?

Responds Grande, “just as a carbon footprint measures the amount of GHG emissions within a specific operation, a chemical footprint strives to understand and measure the amount of potentially hazardous materials within a specific operation to aid in reduction.”

Sustainability and packaging

Packaging programs and initiatives are fundamental to members’ sustainability plans, especially regarding the use of plastic packaging for cleaning products.

“Product packaging is essential to the safe transportation and storage of products,” Grande tells PlasticsToday. “A package is needed to protect the contents inside over a long period of time and provide safety to the user. Plastic has often been a preferred material due to its ability to withstand degradation from the chemicals within, potential ability to be recycled across the U.S., and because of its lightweight nature.”

Plastics are foundational to ACI members’ packaging portfolio.

“When it comes to our ambition to optimize the use of natural resources and eliminate waste, packaging needs to be a major priority,” continues Grande. “Not only do members need to reimagine packaging to limit waste, but recovery rates also need to be improved. That means helping consumers understand what to do with an empty package, as with initiatives like the How2Recycle program.”

Members have been proactive on their own, according to Grande.

“We’re seeing many of our companies make commitments to improve the recyclability of their packages—32% of ACI product formulators—and move toward more renewable or recycled raw material sources—35% of ACI product formulators,” she says. “As these commitments come to fruition through collaborations with packaging suppliers, I expect more tactics on implementation will be shared.”

As referenced earlier, cleaners have specific challenges from a packaging sustainability view.

“Cleaning products often contain chemicals that can degrade packaging over time, so the packaging must be designed robustly enough to withstand such conditions,” Grande explains. “Packaging for foods and other less aggressive products typically do not face this challenge.

“And unlike foods that are often consumed quickly after purchase and therefore must only contain the product for a relatively short time, cleaning products are typically kept for much longer by the consumer and therefore the packaging must be designed to last much longer.

Next: Polymers, PCR content and Loop

“Certainly one of the biggest tasks for packaging is product protection—every product has different needs during their lifecycle like ‘stored safely’, ‘stay effective’, ‘stay fresh’, ‘look good’, ‘different supply chains’, etc., so the  package needs to be engineered to deliver against these requirements,” continues Grande. “Solutions are provided by resin choices, additives—UV-blocker, barriers, oxygen scavengers, colors, etc.—and special solutions including mixed-material packaging, for example multilayer pouches.

package needs to be engineered to deliver against these requirements,” continues Grande. “Solutions are provided by resin choices, additives—UV-blocker, barriers, oxygen scavengers, colors, etc.—and special solutions including mixed-material packaging, for example multilayer pouches.

“Each solution will have a different impact on sustainability.”

And then there’s probably one of the largest issues in the cleaners market, Environmental Stress Crack Resistance.

“ESCR disproportionally effects cleaners in the use of HDPE PCR,” Grande points out. "HDPE is a common polymer in this market and a number of brands have been adding PCR HDPE to increase their packaging’s sustainability. Due to the nature of PCR plastics, there is increased risk in chemical products interacting with the material, resulting in cracking. Processing of the resin throughout the molding process and properly designing bottles for use of PCR are critical steps to prevent this.”

Other packaging-related challenges noted by the ACI:

Lack of infrastructure to collect laundry and other home care bottles versus beverage bottles limits the amount of plastic recovered for reuse;

The intense colors of certain bottles may limit their reuse, thus limiting their value when recycled;

Use of shrink wrap labels can confuse automatic sorters on material recovery lines;

Pumps and closures may not be recyclable;

Pouches are generally not recyclable.

“In order to make our goals more concrete, we are working on outlining the best practices and actions we expect fr om our members,” says Grande. “We plan to share this in the future and use it to indicate how we are doing in achieving our goals.”

om our members,” says Grande. “We plan to share this in the future and use it to indicate how we are doing in achieving our goals.”

With the increasing scarcity of natural resources, ACI acknowledges the need for a new type of thinking in an effort to move globally toward a more circular economy. Wherever possible, the industry must seek to reduce, reuse or recycle in order to avoid depleting the planet’s natural resources, the ACI asserts.

ACI companies are combating natural resource depletion, pollution and waste through new product forms, packaging redesigns and collective efforts to eliminate problematic or unnecessary packaging and prevent plastic pollution in marine environments.

“32% of ACI formulators have a goal to reach 100% recyclable packaging, and many are modifying labels to helping consumers recycle more easily,” Grande points out.

Members get in the Loop

Members are also relying on external sources to help them reach goals.

Grande informs PlasticsToday that “collaborations are taking the lead in tackling infrastructure related challenges and innovating on new conceptual ideas. The Alliance to End Plastic Waste is bringing together members of our value chain to tackle the problem of plastic pollution. And the Loop initiative is a great example of how companies are working collaboratively in a new space to pilot big ideas with consumers.”

Two ACI member companies, both major brands, shared thoughts about their involvement in Loop, which is a global circular shopping program based on reusable packaging (see Game-changing waste-free shopping platform introduced by TerraCycle at Davos, published January 2019).

PlasticsToday sought information from ACI members about their involvement with Loop, and Colgate-Palmolive (New York City) and The Clorox Company (Oakland, CA) responded.

While Colgate’s Loop Packaging remains under development, the company was willing to share an aspirational image (right) of a potential reusable package and added this explanation: “Reducing waste is a leading sustainability goal for Colgate-Palmolive. Moving away from single-use packaging towards reusable packaging options is one of the approaches under exploration. Colgate is proud to partner with Loop to develop durable packaging designs for mouthwash. The featured package is an aspirational design direction which could be proudly displayed on a countertop while offering sustainable, guilt-free convenience.”

The Clorox Company reported that it has worked with Loop on both its Clorox brand disinfecting wipes (below) as well as Hidden Valley Original Ranch dressings and toppings.

A Clorox representative also provided this information: "The company’s participation in Terracycle’s Loop platform supports our focus on Good Growth—growth that's profitable, sustainable and responsible—by enabling us to explore new circular models for our products. The initiative advances the following corporate commitments related to sustainable packaging:

A Clorox representative also provided this information: "The company’s participation in Terracycle’s Loop platform supports our focus on Good Growth—growth that's profitable, sustainable and responsible—by enabling us to explore new circular models for our products. The initiative advances the following corporate commitments related to sustainable packaging:

50% reduction in virgin plastic and fiber packaging by 2030

100% recyclable, reusable or compostable packaging by 2025.

For the Loop pilot launch, two of our products are participating in the program’s Mid-Atlantic region: Clorox disinfecting wipes (crisp lemon) and Hidden Valley Original Ranch topping and dressing.

The company also shared plans to add Glad food protection product to the platform later this year.

To participate in Loop, our brand teams had to source or design packaging strong enough to withstand 100 uses or refills, resulting in a double win of more durable and reusable packaging designs that are also more visually appealing for the consumer."

You May Also Like