A $2.7-million R&D agreement between AddUp Group (Clermont-Ferrand, France) and Oak Ridge National Laboratory (ORNL) aims to advance laser powder bed fusion technology for the manufacture of metal molds with complex geometries.

January 6, 2020

When metal 3D printing came on the industrial manufacturing scene some two decades ago, it experienced the same long slog to success as 3D printing for plastics. As technology advanced and materials became more available for the process of direct metal laser sintering (DMLS), it found more industrial applications. While DMLS has been implemented by a handful of mold makers to produce mold components, especially conformal cooling channels, most mold shops pooh-poohed the idea that an entire mold could be made by this process. As I watched the additive manufacturing industry evolve, however, I often warned mold makers that one day metal 3D printing might be able to create molds. That day may have arrived.

A $2.7-million cooperative research and development agreement between AddUp Group, a global machine and solutions provider for metal additive manufacturing (AM) headquartered in Clermont-Ferrand, France, and the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL) aims to advance laser powder bed fusion (LPBF) technology for the manufacture of metal molds with complex geometries for the tooling industry.

|

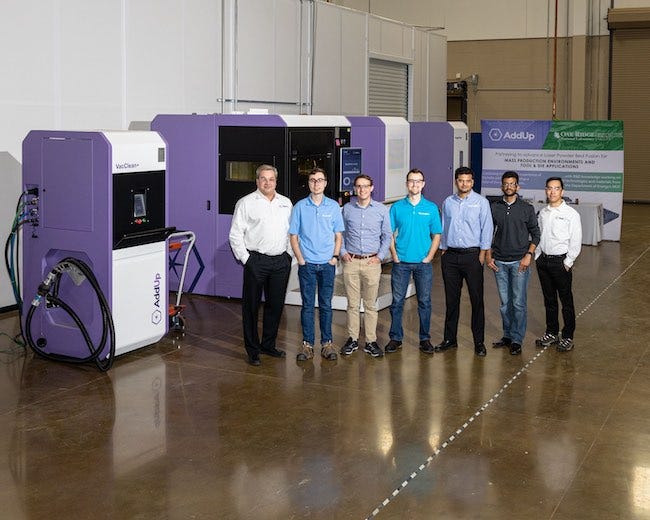

Members of the Oak Ridge National Laboratory and AddUp collaborate to advance metal 3D printing for the fabrication of complex mold and die tooling that will lead to reduced cycle times and optimized, repeatable performance. Image courtesy AddUp. |

AddUp provides a unique industrial approach to metal 3D printing informed by the inherited expertise of its two founders, industrial groups Fives and Michelin. The AddUp Group, which has its U.S. subsidiary in Greenville, SC, was established in April 2016 when Fives and Michelin decided to create a major global player in metal 3D printing. The joint venture uses its experience and unique knowledge to benefit clients by developing and marketing industrial machines and production systems based on metal AM technology. The AddUp Group offer includes FormUp LPBF and BeAM Directed Energy Deposition (DED) technologies.

AddUp explained that it offers multiple integrated technologies, capabilities and comprehensive solutions, including machines and systems, training and consulting, design for AM, and proof of concept. These precision systems are “highly productive, capable of fine-resolution printing, and are paired with the flexibility of an open architecture framework for materials and parameters.”

AddUp’s involvement at the DOE Manufacturing Demonstration Facility (MDF) at ORNL centers on the development of industrial LPBF technology, with a specific focus on the advancement of metal AM applications for tooling. By improving the deposition rate within powder bed technologies, closely controlling the metallurgical processes and managing the qualification of steel tooling components, this project is expected to advance metal 3D printing overall.

ORNL contributes an in-depth understanding of material properties and process parameters that leverages in-situ data analytics and advanced machine learning tools. The use of MDF’s cutting-edge methods of characterization will expedite the delivery of validated AM process recipes and a deepened comprehension of the micro-structural properties of AM tool steels. The pooled expertise of AddUp and ORNL enables the fabrication of complex mold and die tooling that will lead to reduced cycle times and optimized, repeatable performance, said AddUp’s information.

The cooperative R&D agreement focuses on the development of breakthrough solutions for the geometric constraints and limitations—overhang angles, thin walls, process repeatability and so forth—that impede the wide adoption of metal AM for tooling and mass production environments. For example, many challenges in the plastic injection molding industry can be overcome by using complex cooling channels.

AddUp and ORNL will explore the impact of these complex channels to advance applications. Subtractive, conventional methods that use traditional machinery hinder the design of intricate channels within the mold. This collaborative effort aims to deliver a technology capable of improving pre-existing processes of manufacturing conformally cooled molds with optimized mechanical properties, productivity and quality for enhanced performance in high-volume production environments.

About the Author(s)

You May Also Like