ultrasonic metal welding GMX Micro D Type.jpg?width=700&auto=webp&quality=80&disable=upscale)

Manufacturing.jpg?width=700&auto=webp&quality=80&disable=upscale)

Ultrasonic Metal Welding Evolves to Meet Energy Storage System Manufacturing NeedsUltrasonic Metal Welding Evolves to Meet Energy Storage System Manufacturing Needs

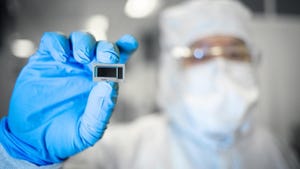

Thanks to its use of high-frequency vibration and pressure to bond metals without melting, ultrasonic welding offers battery producers a promising alternative to traditional welding.

Sign up for the Design News Daily newsletter.

.gif?width=300&auto=webp&quality=80&disable=upscale)

.jpg?width=100&auto=webp&quality=80&disable=upscale)