Force sensing helps hydrogen electrolyzers efficiently harness energy.

November 29, 2022

Randy White, OEM Business Development Manager, Interface.

The use of hydrogen as a clean and reliable renewable energy source has been a carrot on a stick for green energy innovators for many, many years. Scientists and technologists have understood the positive impact of hydrogen for a long time, and even harnessed it at times, but the ability to reliably store and harness this energy at a reasonable cost has previously eluded them. However, hydrogen is back in full force as storage and battery technology has advanced, giving new life to the promise of hydrogen.

Hydrogen is critical to the future of green energy because it is an optimal solution to storing renewable energy from other sources such as wind and water. In certain areas, like California, we’re actually producing too much energy from renewable sources, but have no place to store. This is leading to a tremendous amount of resource loss. Therefore, hydrogen innovation has come back to become a storage solution to curtail waste and hold enough energy to power more infrastructure with green energy.

The road to get to a place where hydrogen could become a real solution to meeting the renewable energy demand has been filled with hundreds of technological advancements. One of those solutions are hydrogen electrolyzers. This is a device that use the process of electrolysis to produce and store hydrogen for an indefinite amount of time. Electrolysis is a promising option for carbon-free hydrogen production from renewable and nuclear resources.

Electrolysis produces hydrogen

Electrolysis uses electricity to split water into hydrogen and oxygen. This reaction takes place in an electrolyzer. Electrolyzers can range in size from small, appliance-size equipment that is well-suited for small-scale distributed hydrogen production to large-scale, central production facilities that could be tied directly to renewable or other non-greenhouse-gas-emitting forms of electricity production.

Over the past few decades, organizations have invested in these ‘electrolyzer farms’ to harness more energy. However, electrolyzers are volatile in their current construction. The electrolyzer is made by stacking multiple anode and cathode plates and a membrane between each, and these are held together by gigantic tie-rods that secure the unit. Over time the rods loosen and can leak a tremendous amount of energy.

It is recommended that the users inspect the electrolyzers periodically to check for leaks or damage. To do this, 10 or more electrolyzers in a line need to be taken down for inspection. This is not only an inefficient process, but it can lead to tremendous waste. Therefore, more engineering innovation has been necessary to improve the promise of electrolyzer farms.

The role of force sensing

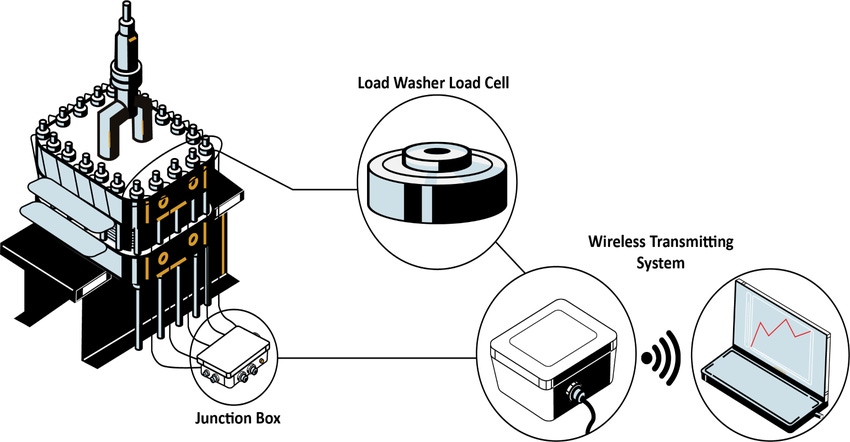

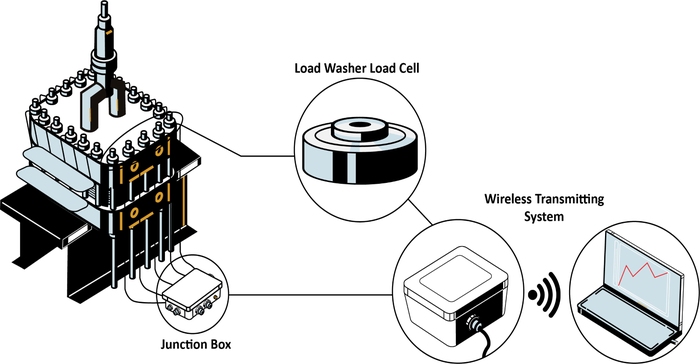

This is where force sensing comes into the equation. To reduce the downtime of an electrolyzer, load cells can be used to measure the tie rod in real time. To do this, load cells are secured to the tie rod and connected to a strain bridge transmitter. This allows the user to always monitor the tension of the tie rod.

What this creates is autonomous monitoring system that will tell users exactly when repairs or inspection is needed, rather than a manual monitoring system that may shut down a portion of electrolyzers when it isn’t necessary creating waste and unnecessary downtime. Not to mention, the cost of downtime in electrolyzers over time is significant compared to the one-time cost of purchasing a force measurement system to alert the user when repair is needed more accurately. In fact, I estimate that a customer would break even in the first year after purchasing a load cell monitoring system.

Also, load cells can last an infinite amount of time with the proper calibration and electrolyzers rarely ever cycle, which reduces the opportunity for damage to the load cell. This means that this is a solution that will last as long as needed.

Included below is an image that visualizes the process for monitoring an electrolyzer unit using load cells.

Now is the time to truly invest in the promise of hydrogen energy to meet or needs for green energy. Electrolyzers have been around for a while, there was a big push in nineties for this technology. However, the right elements were not there politically, economically, or climate crisis wise. Now we are running out of time as global warming becomes an ever-looming threat pushing governments to mandating green energy innovation and usage.

With force sensing capabilities, electrolyzer farms have become a real solution to help store massive amounts of green energy, while reducing waste significantly.

You May Also Like