November 21, 2015

High-performance polymers have been making inroads in high-heat, under-hood car environments for awhile now. At some recent industry events, DuPont Performance Polymers showed off several new parts made of polymers designed for these uses.

In collaboration with DuPont and powertrain system and component supplier ElringKlinger, Daimler AG developed a series of structural engine brackets made of DuPont Zytel PA66 resin. The brackets must support engine torque stresses and high static loads, and this optimized grade of Zytel PA (polyamide) -- a glass fiber-reinforced, heat-stabilized nylon -- can replace standard die-cast aluminum. It combines strength, stiffness, low heat conductivity compared to metals, and resistance to creep, deformation and fatigue to stand up to load and stress. It also absorbs noise, vibration, and harshness.

The team used DuPont's advanced anisotropic CAE modeling capabilities that predict automotive part performance. Micro-mechanical material modeling with Digimat was used to optimize the FEA (finite element analysis) of the glass-reinforced materials, accurately analyze local changes in material properties, and identify any structural weaknesses in the design. Such predictive capabilities have become a regular part of application development in validating design solutions to reduce cost and time to market, said Patrick Cazuc, global automotive manager for DuPont Performance Polymers, in a press release. The company exhibited the brackets at the Fakuma 2015 show last month in Geneva, Switzerland.

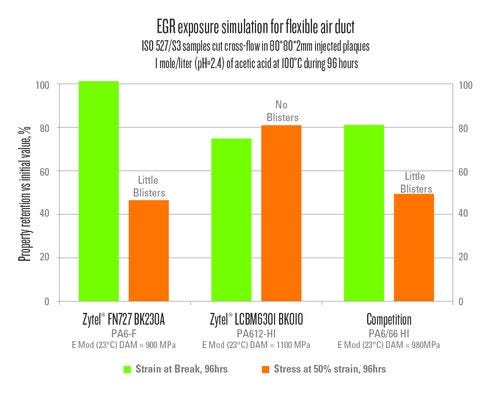

Also at Fakuma, DuPont debuted three new materials for operation in the latest compact, turbo-charged diesel and gasoline engines. The first two, Zytel LCBM6301 and Hytrel HTR8797, are both blow-moldable, and were developed to resist high temperatures and acid while providing durability in air ducts.

The Zytel grade is a long-chain PA612-HI with acid and thermal resistance superior to that of flexible PA6, and better thermal resistance than PA12. It's targeted at flexible automotive air ducts, positive crankcase ventilation tubes, and exhaust gas recirculation sensor tubes. The flexible Hytrel resin more than doubles the 130C -150C air oven aging durability of previous Hytrel grades specified for cold-side blow-molded auto air ducts. DuPont says both new grades are up to 50% recyclable without impacting the material's final properties.

READ MORE ARTICLES ON PLASTICS IN CARS:

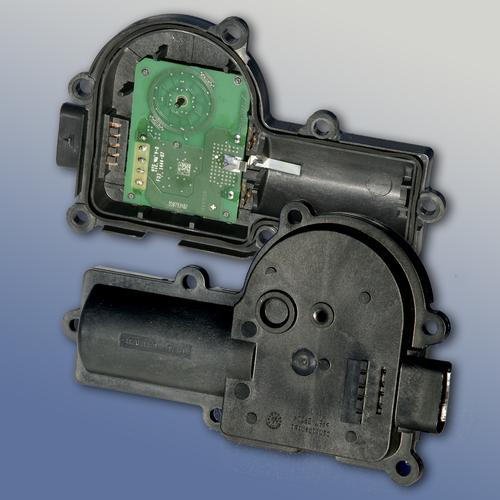

The third new polymer is a direct drop-in replacement for standard PBT (polybutylene terephthalate) on existing injection molding machines. Crastin Super Fast (SF) PBT is more efficient at lower filling pressures, which improves resin flow up to 30% compared to standard grades. Its improved processing performance enables the design of thinner, lighter parts with greater complexity in electrical and electronic applications such as automotive sensors, relays, control units, coil formers, switches, and solenoids.

Because of its shorter cycle time and better mold-filling characteristics, auto components supplier Continental Automotive specified Crastin SK615SF PBT for a series of thermal covers that protect a sensor module controlling the engine thermal management system, said the company's senior technical expert -- injection molding technology Regis Sarrahy -- in a press release. Compared to the PA traditionally used for these parts, the new PBT has very low moisture pickup, significantly reducing moisture degradation of encapsulated electrical devices.

Earlier this month DuPont, along with Honda and Delphi Automotive, won an award for the most innovative use of plastics in the powertrain category at the 45th Society of Plastics Engineers Automotive Innovation Awards. The team developed the Delphi Multec 3.5 Heated Tip Port Fuel Injector for use in Honda Fit and Honda City cars that run on 100% ethanol, like those sold in Brazil. The injector improves cold-start performance in ethanol-fueled vehicles, a pervasive issue, said Dave Dues, Delphi Flex Fuel Vehicles Program chief engineer.

The Multec 3.5 Heated Tip Port Fuel Injector has an integrated heating device that rapidly heats ethanol fuel so it can evaporate and be ignited more efficiently in cold weather. The integrated component, overmolded with Zytel HTN PPA (polyphthalamide), eliminates the need for a secondary gas tank, commonly used to improve cold start. It reduces weight by 9 kg, improves fuel economy, lowers emissions, and significantly lowers cost.

Zytel HTN PPA was chosen for overmolding the component because of its lower melt viscosity compared to other PPAs, which helps protect the sub-assembly during molding. This material is often used in engine cooling components, as well as fuel line quick connectors, due to its resistance to heat and chemicals, especially long-life coolant. It also offers better elongation than other PPAs to survive thermal cycling without stress cracking. For this application, DuPont developed a new, electrically friendly, heat-stabilized grade.

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 27 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

Like reading Design News? Then have our content delivered to your inbox every day by registering with DesignNews.com and signing up for Design News Daily plus our other e-newsletters. Register here!

Design engineers and professionals, the West Coast's most important design, innovation, and manufacturing event, Pacific Design & Manufacturing, is taking place in Anaheim, Feb. 9-11, 2016. A Design News event, Pacific Design & Manufacturing is your chance to meet qualified suppliers, get hands-on access to the latest technologies, be informed from a world-class conference program, and expand your network. (You might even meet a Design News editor.) Learn more about Pacific Design & Manufacturing here.

About the Author(s)

You May Also Like