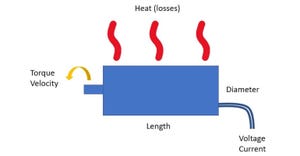

Motors, Actuators, Conveyors

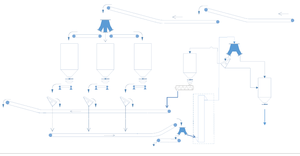

spaced-based robot surgeon

Industry

Surgical Robot Heads for Space and Supplier NewsSurgical Robot Heads for Space and Supplier News

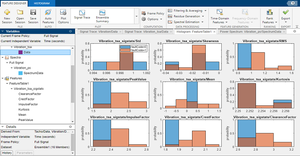

We’re also checking out low-voltage servo systems, capacitive level sensors, and surface-mount devices.

Sign up for the Design News Daily newsletter.