It sounds like science fiction, but it's not. 3D-printed human ear, bone, and muscle tissue have been implanted in lab rats and successfully grew their own blood vessel networks.

February 24, 2016

It sounds like science fiction, but it's not: 3D-printed human ear, bone, and muscle tissue have been implanted in lab rats and successfully grew their own blood vessel networks. We've been hearing about this for a few years now: different groups of researchers working on 3D-printing processes and materials that can print living human tissue to replace various body parts and organs. It's already been done with liver tissue, but that's for use in drug testing and research, not implants.

A team of scientists working in regenerative medicine at Wake Forest Baptist Medical Center developed their own 3D printer for making stable human tissue of any shape, to replace injured or diseased tissue. One of the biggest challenges to tissue engineering is getting implanted structures to live long enough while they're becoming integrated into the body. Funded by the Armed Forces Institute of Regenerative Medicine, the research is part of its mission to develop regenerative medicine techniques that can be used for injuries sustained on the battlefield.

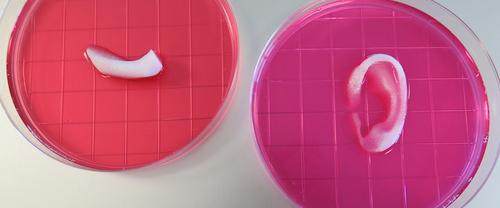

3D-printed ear and other tissue implants made with the new Integrated Tissue and Organ Printing (ITOP) 3D printer developed by a team of scientists at the Wake Forest Institute of Regenerative Medicine.

(Source: Wake Forest Institute of Regenerative Medicine)

The researchers custom-built a 3D printer, the Integrated Tissue and Organ Printing (ITOP) system, since existing 3D printers based on methods such as extrusion or jetting can't make structures that are big enough, strong enough, and have enough structural integrity to be implanted in humans. It uses clinical imaging data from CT and MRI scans as the computer model of the anatomical defect, and translates that model into a program that directs the printer nozzles' motions, so they dispense cells in the right locations.

As you can see in this short time-lapse video, the ITOP 3D printer produces hydrogels full of cells, as well as biodegradable polymer materials that form the shape of the desired implant, plus a temporary outer structure.

The water-based ink -- the hydrogels that hold the cells -- used in the ITOP is optimized to promote cell health and growth. Also, a lattice of micro-channels is printed throughout the implant structures, which let the body's nutrients and oxygen diffuse into the structures to keep them alive while they are developing their own networks of blood vessels. The ITOP system was developed over a decade by scientists at the Wake Forest Institute of Regenerative Medicine.

As they describe in an article in Nature Biotechnology, the scientists were successful in printing ear, bone, and muscle structures that, when implanted in animals, grew into functional tissue and developed their own blood vessel systems within two months. Based on these initial results, the team believes the structures they grew are the right size, and have the correct strength and functioning to be used in humans.

READ MORE ARTICLES ON 3D PRINTING IN MEDICAL APPLICATIONS:

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 28 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

About the Author(s)

You May Also Like