Hierarchical Surface Restructuring technology can be used to enhance charge storage capacity, increase specific capacitance, & decrease impedance of electrodes & microelectrodes.

June 29, 2022

A novel surface modification technology is helping a medtech company develop a new solution for treating heart failure.

Cardionomic Inc. is developing the Cardiac Pulmonary Nerve Stimulation (CPNS) System for treating patients suffering from Acute Decompensated Heart Failure (ADHF). Currently an investigational device in the United States, CPNS is designed to increase contractility of the heart to pump more blood to the rest of the body, according to the company.

To develop the device, Cardionomic has employed Hierarchical Surface Restructuring (HSR) technology from Pulse Technologies Inc., according to Steve Goedeke, CEO of Cardionomic.

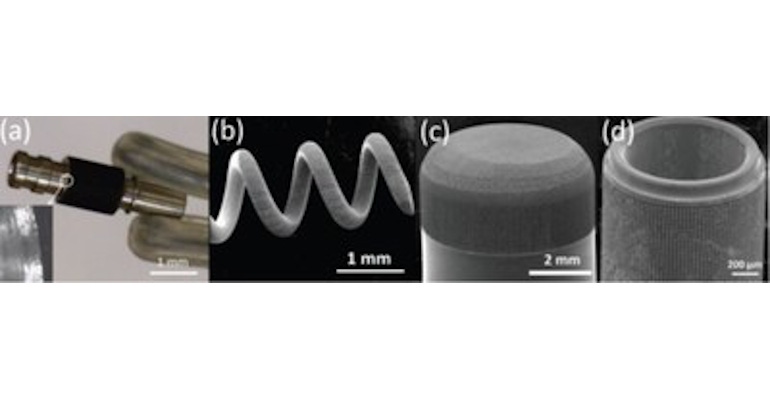

HSR is an advanced surface treatment technology that can be used to modify the surface of implantable electrodes and microelectrode arrays using ultrashort pulse lasers, Shahram Amini, PhD, director of R&D for Pulse Technologies, told Design News. “The primary intent is to increase the electrode surface area to improve and tune electrochemical performance of the device,” he explained. Its impact on electrochemical performance could help enhance charge storage capacity, increase specific capacitance, and decrease impedance.

It is different from other surface treatments in that HSR truly modifies surfaces. “Most other treatments are additive coatings,” Amini said. “Coatings can be subject to cracking, flaking, delamination, and spallation. HSR by contrast is tunable, providing a truly engineered surface morphology.”

HSR may enable “miniaturization of electrodes and microelectrode arrays by increasing electrochemical surface area,” as it can support production of “smaller electrodes with enhanced electrochemical performance, durability, selectivity, and resolution,” Amini explained. “More importantly, through our enabling of more efficient electrodes through this process, the battery life of active implantable devices can be extended.”

Potential applications for HSR include neuromodulation, cardiac rhythm management, electrophysiology mapping catheters, and cochlear implants, Amini said. And “some new applications we are investigating are in the diagnostic area and in the area of industrial seals,” he added.

Pulse began development and initial commercialization of HSR just over 5 years ago, Amini said. “As awareness of this technology grows, various customers from different industries contact Pulse to push the boundaries of HSR capabilities. Through research and development projects even Pulse continues to gain an understanding of the versatile value it can provide in seemingly limitless applications,” he said.

About the Author(s)

You May Also Like