An industrial robot known for its safety around humans has been programmed to work a checkout lane and choose how it accomplishes certain tasks.

December 11, 2013

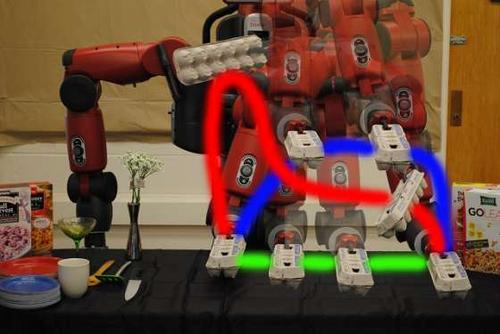

You won't be meeting the big, red Baxter robot anytime soon in your local supermarket. But the soft-surfaced, slow-moving industrial robot known for its safety around humans has been programmed to work a checkout lane and choose how it accomplishes certain tasks.

Rethink Robotics' Baxter can already work a simple pick-and-place production line, and it can do so even more accurately after its recent 2.0 software upgrade. A Cornell University team led by doctoral candidate Ashesh Jain, under the tutelage of assistant professor of computer science Ashutosh Saxena, programmed a modified Baxter robot to work as a checker.

Click the photo below to check out our slideshow.

With multiple joints, a Baxter robot can move more flexibly than a human. Since it would be hard for a human to decide how to use those arms, the robot is programmed to plan its own movements and then allow humans to make corrections. As a first step, it computes three possible trajectories for moving an object and displays them on a touchscreen. After an operator selects one, the robot goes through the motions of that trajectory,

and the operator can make refinements.

(Source: Cornell University)

Like a human checker, the robot had to handle objects with different sizes, shapes, and fragility. A carton of eggs can't be tossed around like a box of cereal. Also, a sharp object like a knife shouldn't be moved in a trajectory that takes it too close to a human.

The Cornell University Personal Robotics Lab has been working on "coactive learning," helping humans and robots cooperate to accomplish tasks. An essential part of this approach is a robot's ability to adapt to people; it must be able to make some decisions on its own. The team taught Baxter to plan its own actions and gave it feedback in multiple iterations.

This is possible partly because Baxter 2.0's movements can be programmed using Waypoints. These let users define the specific trajectories of Baxter's arm movements very precisely by modifying a given trajectory while it's in progress to avoid obstacles or to place items in a certain way. Users train Baxter by pushing its arms into each point along the path and then pushing a button to set those points in memory.

As shown in this YouTube video, the Cornell researchers give corrective feedback to teach Baxter to use shorter trajectories to keep knives away from people. Baxter then knows which of several trajectories should be preferred for a given object in a given context. The team gave similar feedback for handling a carton of eggs; the robot learned not to lift it too high off the counter and to keep it upright and horizontal.

The team presented a paper on its work last week at NIPS (Neural Information Processing Systems) 2013 in Lake Tahoe, Calif.

Related posts:

{doclink 270169}

{doclink 270141}

{doclink 268699}

{doclink 268253}

{doclink 268173}

{doclink 267732}

{doclink 266916}

{doclink 263495}

{doclink 263186}

{doclink 261138}

{doclink 260644}

{doclink 259420}

{doclink 258622}

{doclink 258342}

{doclink 257502}

{doclink 257119}

{doclink 256841}

{doclink 256018}

{doclink 254726}

{doclink 254277}

{doclink 254180}

{doclink 254000}

{doclink 253921}

{doclink 252739}

{doclink 251721}

{doclink 250592}

{doclink 250357}

{doclink 248568}

{doclink 247989}

{doclink 247655}

{doclink 246646}

{doclink 245683}

{doclink 245355}

{doclink 244587}

{doclink 240629}

About the Author(s)

You May Also Like