Heraeus and Exmet have successfully 3D printed amorphous metals. This is no small feat: these materials, also called liquid metals or metallic glass, haven't exactly been easy to produce using conventional manufacturing methods.

July 13, 2016

Germany-based precious metals expert Heraeus and Swedish startup Exmet have successfully 3D printed amorphous metals. This is no small feat: these materials, also called liquid metals or metallic glass, haven't exactly been easy to produce using conventional manufacturing methods.

Why would you want to work with liquid metals? Because their combined characteristics aren't found together in conventional metals, due to a different atomic structure. Most conventional metals are crystalline when solid, versus amorphous metals, which have a disordered, non-crystalline structure more like glass, created when metal cools very quickly. Compared to conventional metals, liquid metals are harder, more corrosion-resistant, and combine both high strength and malleability, said Tobias Caspari, head of 3D printing at Heraeus New Businesses.

Heraeus and Exmet have successfully 3D printed amorphous metals using a process that promises to build larger parts with more complex shapes than have been possible with conventional processes.

(Source: Heraeus)

Amorphous metals are scratch-proof and energy-absorbing, yet retain good spring characteristics. These qualities make them good for consumer electronics casings, diaphragms in injection nozzles, and dome tweeters for speakers. Caspari said the two companies intend to use these materials and Exmet's patented process to commercialize amorphous metals for various industrial uses.

Although amorphous metals have been produced and used in limited quantities for making small parts for several decades, their commercial success has been held back by inadequate manufacturing methods, said Exmet's co-founder and CEO Mattias Unosson. According to the company's website, the additive manufacturing (AM) process it has been developing for these materials can fabricate products made of almost any metal alloy -- including iron, titanium, aluminum, magnesium, or cobalt -- and of almost any shape.

READ MORE ARTICLES ON 3D PRINTING:

Heraeus, which has been developing 3D printing metal powders for some time, has been experimenting with 3D-printing processes and metal powder materials in tandem because of the importance of matching the component to be printed with a specific metal powder and printing process. According to an article in the company's 2014 annual report, the aim is to reduce the cost of manufacturing and improve product quality for its customers. The company has previously used AM for prototyping customers' metal parts, but is now developing 3D printing powders of refractory precious metals and special alloys to produce its own materials. The goal is to make small quantities of such parts for aerospace, medical, and automotive industries, as well as parts to be used internally at the company's own plants.

"We are experimenting with mixtures of different substances and can thus do research into materials with new characteristics," said Dr. Hans-Juergen Wachter, executive vice president of technology & scouting for Heraeus New Businesses. The company is focusing on high melting metal powders, and is currently testing binder jetting and laser sintering processes. It has already purchased two plants for 3D printing: an electron beam furnace and a 3D laser plant. With these, it can conduct smelting and printing trials with different materials.

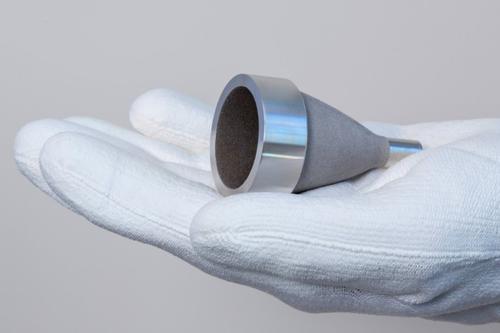

This satellite thruster nozzle was 3D printed with a conventional platinum-rhodium 20 alloy powder from Heraeus for a European Space Agency project. It was successfully hot-fire tested, and the first satellite with 3D-printed thruster nozzles is planned to launch next year.

(Source: Heraeus)

Satellite thruster nozzles have already been 3D printed with one of Heraeus' conventional metal powders, a platinum-rhodium 20 alloy. As part of a European Space Agency project, the thruster passed a hot-fire test last fall at Airbus' Defense & Space facility in Germany. The first satellite with 3D-printed thruster nozzles is planned for launch in 2017.

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 28 years, covering manufacturing materials & processes, alternative energy, machine vision, and all kinds of communications.

About the Author(s)

You May Also Like