Scientists have used the changing composition of oil as inspiration for a new method for generating complex shapes, paving the way for new shape-shifting materials with a range of applications.

February 25, 2016

Scientists have used the changing composition of oil when it’s frozen as inspiration for a new method for generating complex shapes, paving the way for new shape-shifting materials that could have applications in pharmaceuticals, paint, and household products.

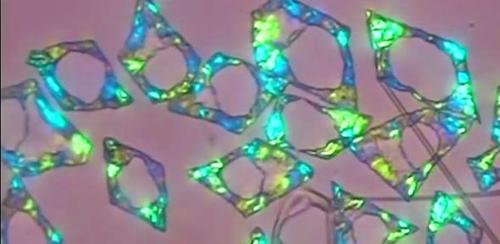

Researchers from the University of Cambridge and Sofia University in Bulgaria observed droplets of oil in a soapy water solution that were slowly changed from a liquid state to a solid, finding that plastic-crystal phases that formed on the inside surfaces of the droplets caused them to change shapes into a variety of forms. Those shapes included octahedrons, hexagons, triangles, and fibers, according to researchers.

Researchers have been using examples of how biological materials change shape to inspire new ways to create synthetic materials that can perform similarly. But so far they haven’t cracked the code of how to control the process to make the materials do what they want, said Dr. Stoyan Smoukov from Cambridge’s Department of Materials Science and Metallurgy, the leader of the research. The team published their findings in an article in the journal Nature.

“There are many ways that non-biological things take shape,” he said. “But the question is what drives the process and how to control it -- and what are the links between the process in the biological and the non-biological world?”

Scientists have used the changing composition of oil as inspiration for a new method for generating complex shapes, paving the way for new shape-shifting materials that could have applications in pharmaceuticals, paint, and household products.

(Source: University of Cambridge)

The new finding differs from previous efforts to create complex shapes with materials, which use top-down processing methods that allow for control but aren’t efficient in terms of the amount of material used, researchers said. These previous methods also require expensive equipment to make the shape.

On the contrary, the new method takes a simple, bottom-up approach to create complex shapes, and also challenges a long-held theory proposed in the 1950s by code breaker and mathematician Alan Turing as to what drives the shape-shifting process, called morphogenesis, Smoukov said.

In animals, morphogenesis controls the distribution of cells during embryonic development; it also drives the growths of cancerous cells in tumors. Turing proposed that reaction-diffusion -- which is when chemical reactions cause a substance to spread through a space -- is the catalyst for morphogenesis.

However, the research of Smoukov and his team, as well as the work of other researchers with separate projects, is challenging this notion. Instead, it suggests that the physical properties of materials control the morphogenesis process, something Turing anticipated but could not determine during his time without computers.

READ MORE MATERIALS ARTICLES ON DESIGN NEWS:

The recent research helps prove this theory through the activity of the oil droplets. As they slowly freeze in a soapy solution, they shift shape through a variety of different forms, and then shift back to their original shape if the solution is rewarmed, researchers said. Further observation found that the self-assembly of a plastic-crystal phase forms beneath the surface of the droplets, driving the morphogenesis.

“If we’re going to build artificial structures with the same sort of control and complexity as biological systems, we need to develop efficient bottom-up processes to create building blocks of various shapes, which can then be used to make more complicated structures,” Smoukov said. “But it’s curious to observe such life-like behavior in a non-living thing -- in many cases, artificial objects can look more ‘alive’ than living ones.”

He said it’s the plastic-crystal phase of the oil’s shape shifting that seems to be what’s causing the droplets to change shape, and understanding what is causing this break in symmetry is key to the development of new materials synthetically that do the same. Researchers were able to exert some control over this process by altering the size of the droplets or the rate that the temperature of the solution was lowered. However, while the new research does not fully unlock this mystery, it does provide a foundation for developing pharmaceutical and other household materials that use small-droplet emulsions, Smoukov said.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 15 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like