As consumer, commercial, and industrial electronics continue to shrink, run faster, and have higher performance levels, EMI shielding, weight reduction, and heat dissipation will continue to challenge design engineers and OEMs across the country and around the globe and require innovative board-level shielding as well as close collaboration between design and manufacturing.

January 6, 2016

The first commercially available handheld mobile phone was the Motorola DynaTAC 8000x, which was introduced in 1983. Nicknamed “the brick phone,” it weighed 32 ounces and represented quite an advancement compared to the very first cellphone the company introduced 10 years earlier that was slightly more than 9 inches long and weighed 2.5 pounds.

Compare that to today’s iPhone 6, which is 5.4 inches long and weighs 4.6 ounces. That’s just a little more than one-tenth the weight of the Motorola. While cellphones have shrunk over the years, today’s consumer electronics manufacturers are continually pressured to create lighter yet more powerful devices. And just like consumer goods, today’s electronic gear for commercial and industrial applications must be lighter, smaller, and faster than the previous generation.

This requires the use of more complex circuitry contained in more confined spaces, which leads to a greater level of potential electromagnetic interference (EMI). Moreover, there’s greater demand for devices to do more, and that requires faster processors, which generates more heat that must be dissipated quickly.

Optional solutions

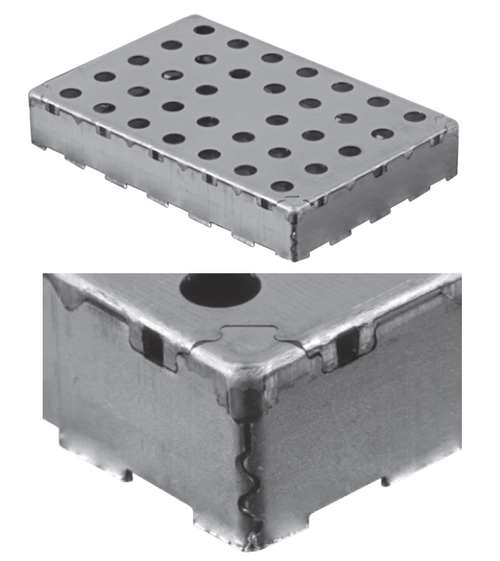

A one-piece board-level shield.

(Source: Laird)

There are a number of options to consider in achieving these design goals. The use of board-level shielding with an integrated thermal management solution is one way to dissipate heat and protect circuitry from EMI.

Lightweight materials like aluminum can be used to simultaneously manage EMI and heat, satisfying thermal management requirements while reducing the product’s weight. In most board-level shield applications, the trade-off of using aluminum versus traditional higher-strength steel is not a critical issue. For the handful of applications where mechanical strength may be crucial, application-specific design and/or the use of high-strength aluminum alloys can address this issue.

Aluminum was introduced in the mid-1990s as a viable material for board-level shields because it allowed for much lighter products while also dissipating a greater amount of heat than typical shielding solutions. Aluminum board-level shields became quite popular in the consumer electronics industry during that time, and since 2000, Laird has shipped more than 30 million aluminum board-level shields to OEM customers.

But aluminum is not the only option for space- and heat-conscious designers. So the question becomes, how do you know which board-level shield option is right for your specific application? While weight is essential, performance is absolutely critical to success.

The complexities of today's smaller and far more powerful electronics pose several design challenges. EMI shielding performance, for example, needs to be balanced with space, weight, and production constraints. Aluminum’s impact on electromagnetic shielding performance for board-level shields is minimal.

At frequencies under 10 MHz, for example, there may be some advantage to using high-permeability materials like cold-rolled steel. But for most of today’s consumer and industrial applications (handsets, tablets, wireless modules, controllers, etc) -- where frequencies of concern are much higher -- the use of aluminum with appropriate plating options can provide excellent RF shielding results.

You May Also Like