A new system called FS-BOC facilitates the fabrication of connections between photonic components and board-level circuits and optical fibers in photonic chips.

May 4, 2022

Researchers have developed new polymer materials for the advancement of optical sensing for the development of novel photonic devices that can be used in a host of applications, including circuit boards, holographic displays, and virtual reality.

A team at the University of Arizona (UofA) developed a new vinylthiophenol polymer material system based on a system called S-BOC that they’d developed previously. In the new system, researchers partially fluorinated S-BOC to improve its light efficiency for a new set of materials called FS-BOC.

The new system shows lower optical propagation losses than many other optical interconnect materials, allowing for better performance out of photonics and optical devices.

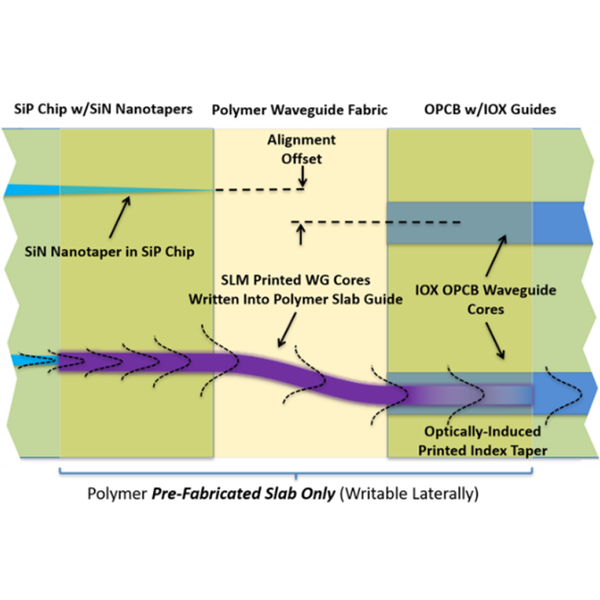

Scientists can use the materials to make the optical links necessary to connect chip-based photonic components with board-level circuits or optical fibers, researchers said. They also are well-suited for creating interconnects between photonic chips and optically printed circuit boards, which are the light-based equivalent of electronic printed circuit boards.

“These new materials and the processes they enable could lead to powerful new photonic modules based on silicon photonics,” said research team leader and UofA Professor Robert Norwood in a press statement. “They could also be useful for optical sensing or making holographic displays for augmented and virtual reality applications.”

Promise of Photonics

Silicon photonics technology allows for the integration of light-based components onto similar chips as to those that process data.

Currently, scientists have the capability and technology for the basic building blocks of silicon photonic devices. However, they are seeking better ways to fabricate the optical connections that link these components together to create more complex systems.

Enter the FS-BOC system of polymer materials, which features a refractive index that can be adjusted with ultraviolet (UV) light and low optical losses.

The materials allow a single-mode optical interconnect to be printed directly into a dry film material using a low-cost, high throughput lithography system, facilitating their manufacturing. This is because the system is compatible with the CMOS manufacturing techniques used to make chip-based photonic components.

“This technology makes it more practical to fabricate optical interconnects, which can be used to make the Internet — especially the data centers that make it run — more efficient,” Norwood explained in a press statement. “Compared to their electronic counterparts, optical interconnects can increase data throughput while also generating less heat. This reduces power consumption and cooling requirements.”

SmartPrint fabrication

Researchers used what is called a SmartPrint process to fabricate the interconnect using the material. This process allows scientists “to directly write optical interconnections between different optical printed circuit board elements,” Norwood said in a press statement.

In the SmartPrint process, researchers apply an FS-BOC film directly to a photonic component without need for mechanical alignment. This is because the optical interconnect is made using a maskless lithography system, which calculates where to place the interconnect by looking at the components and then writing the optical interconnect into the polymer using photo exposure.

The only processing necessary to fabricate the interconnect is to briefly heat the polymer film to 90 °Celsius. Moreover, because the fabrication approach is maskless, writing patterns can be changed without making a new photomask.

Proving the Materials

To demonstrate the materials, researchers deposited them directly onto ion-exchange glass waveguide arrays, which are typically used for integrated photonic devices. They then printed the coupling features necessary so light can travel out of one IOX waveguide, propagate into the newly fabricated polymer interconnect, and then enter a second IOX waveguide next to the initial one.

Researchers published a paper on their research in the journal Optical Materials Express.

Researchers reported that the polymer optical interconnects showed promising performance, including low propagation and coupling losses. This means that as light traveled within the interconnect or between it and the other optical components, very little was lost.

Researchers aim to continue their work to improve the material’s refractive index contrast and performance at high temperatures, Norwood said. This will make the material more tolerant to manufacturing variations, he said.

Moreover, “high-temperature performance is likely needed for the interconnect to withstand solder reflow processes, which take place above 200 degrees Celsius,” Norwood added in a press statement.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like