The 3D printed material, recycled from wool used in apparel fabrication, can provide sustainability in the development of textiles for fitness, medical, and other uses.

November 5, 2020

Researchers at Harvard University have developed a biodegradable and sustainable wool-like material with shape memory that can be 3D-printed to create novel textiles and other products.

A team at Harvard’s John A. Paulson School of Engineering and Applied Sciences (SEAS) developed the biomaterial, which is derived from recycled materials. The materials can be 3D printed into any shape and pre-programmed with reversible shape memory.

The invention is significant not only because researchers created the material was using leftover waste from the textile industry, but it can also help this industry that produces a large amount of waste to become more sustainable.

The team, led by Kit Parker, professor of bioengineering and applied physics at SEAS, developed the material from keratin extracted from leftover Agora and Mohair wool used in manufacturing. Keratin is a fibrous protein found in hair, nails, and shells and also is used in many skin- and hair-care products.

"With this project, we have shown that not only can we recycle wool but we can build things out of the recycled wool that has never been imagined before,” Parker said in a press statement. “The implications for the sustainability of natural resources are clear.”

Shape-Memory Solution

The material developed by the team can be processed into fibers or 3D textiles and, like human hair, has shape memory properties which are triggered by water, explained Luca Cera, a postdoctoral fellow at SEAS who worked on the research.

Shape memory means a material can have both a permanent and a temporary shape, which can be useful to developing more versatile apparel.

“Arbitrary and temporary shapes can be given to the material under specific stimuli,” Cera told Design News. “The material will keep the temporary shape once the stimuli are removed. If the stimuli are applied again, the material will remember the permanent shape and dynamically reconvert into it.”

This characteristic can be applied to the clothing industry to create one-size-fits-all clothing that can stretch or shrink to a person’s measurements, “improving the comfort of garments like brasserie or sportswear,” he said.

“Energy-absorbing devices is another application that could lead to the engineering of more comfortable protection gears,” Cera added.

Material Concerns

Keratin has intrinsic shape memory properties because of the rearrangement of the keratin protein secondary structure, "more specifically its transition from the alpha-helix to beta-sheet,” he explained to Design News.

“This transition can occur under load and triggered in the presence of water,” Cera explained. “We engineered the material in a way that the native fibrillar and hierarchical structure of keratin is preserved so the alpha helices are organized in an anisotropic fashion throughout all length scales and allowing for the shape memory mechanism to occur.”

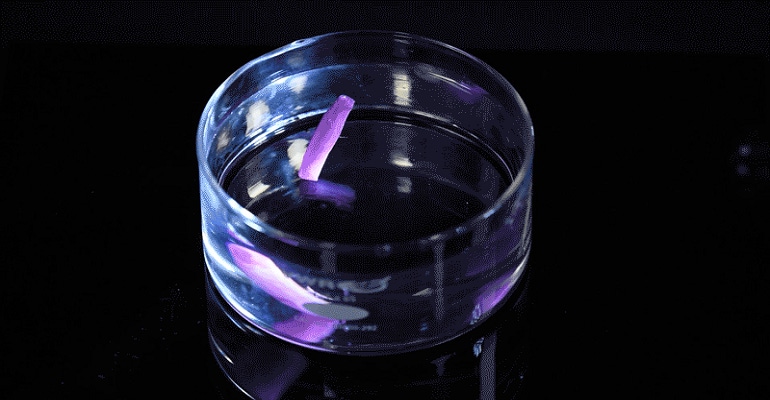

To demonstrate this process, researchers 3D-printed keratin sheets in a variety of shapes, programming the material’s permanent shape using a solution of hydrogen peroxide and monosodium phosphate. This is the shape that the material will always return to after removal of the stimuli that change it.

Once the memory was set, researchers found that they could re-program the sheet and mold it into new shapes.

One test researchers conducted was to fold one keratin sheet into a complex origami star as its permanent shape. They then dunked the star in water, which unfolded it and created malleability, after which they rolled the sheet into a tight tube that dried into a stable shape. They then placed the tube back into water to reverse the process, where it unrolled and folded back into the origami star dynamically.

The team published a paper on its work in the journal Nature Materials.

Future Applications

Researchers are currently discussing how to apply the material to fashion with athletic wear makers, Parker told us.

“There are a variety of applications in clothing that is adaptive to various environments that are achievable with these sustainable, smart materials,” he told Design News.

Other applications for the material that the team is eyeing are in cardiovascular regenerative medicine, Parked added.

From a material engineering perspective, researchers plan to extend the responsiveness of the shape-memory system from water to additional triggers such as light, heat, or chemical messengers, Cera told us.

“Our future research effort will also focus on targeting more specific applications in the textile and tissue engineering and implement fully functional devices based on our shape memory technology,” he told Design News.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like