Researchers at ETH Zurich developed a method to fabricate complex glass objects through additive methods

December 12, 2019

|

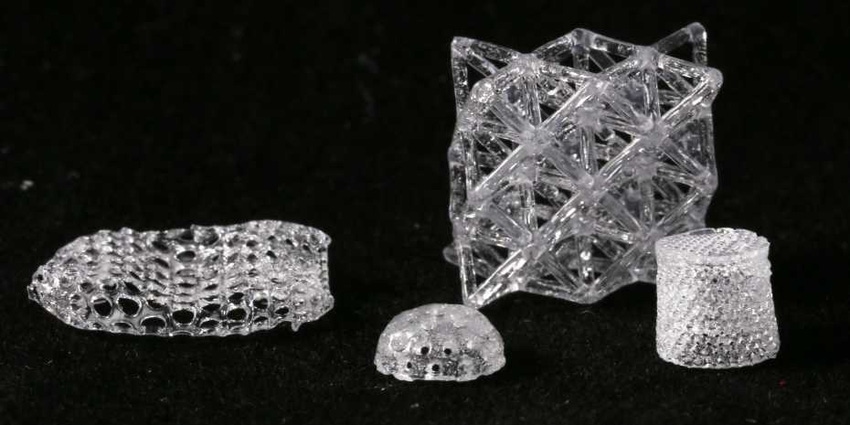

Various glass objects created with a 3D printer using a new fabrication technology developed by researchers at ETH Zurich. (Image source: Group for Complex Materials / ETH Zurich) |

Researchers from ETH Zurich in Switzerland have joined the ranks of small group of scientists who have successfully 3D-printed glass objects. The new method is based on stereolithography, one of the earliest 3D-print techniques, and uses a special plastic-based resin containing glass precursors bonded to organic molecules

Currently, scientists have reported only a few successful processes for 3D-printing glass . A team from the Karlsruhe Institute of Technology (KIT) in Germany printed glass objects in a similar way to the ETH Zurich team—using stereolithography and a combination of polymer and glass. Others have printed molten glass using additive methods.

Other methods have created glass objects in an indirect way by using ceramic particles that are printed at room temperature and then sintered later to create glass. This technique, however, does not allow for the fabrication of complex objects.

Solving material complexity

The technique from the ETH Zurich team solves some of the complications other researchers have encountered through material choice—a resin that can be processed using commercially-available digital light processing (DLP) technology, said Kunal Masania, one of the researchers in ETH Zurich’s Complex Materials group who worked on the project.

DLP applies UV light to the resin, hardening it in the places where it strikes because light-sensitive components of the polymer cross link at these points. The end result combines the plastic monomers to form a structure that creates a polymer, with ceramic molecules filling in gaps in the structure, Masania said in a press statement.

In this way, a glass object can be built up layer by layer, just as typical 3D-printed polymer objects are built, he said. Various aspects of each layer can even be changed to create more complex objects – a result that researchers didn’t plan, Masania added.

“We discovered that by accident, but we can use this to directly influence the pore size of the printed object,” he said in a press statement. Weak light intensity creates large pores in the object, while intense light produces small pores.

RELATED ARTICLES:

Making complex glass objects

Pores aren’t the only parameter of objects that the ETH Zurich researchers can manipulate. According to a paper published in the journal Nature Materials, they can also can change the microstructure of an object layer by layer by adding a mixture of silica and either borate or phosphate to the resin. This means they can fabricate complex objects from different types of glass, or even combine different parts in the same object.

One drawback to this new technique is that it can only print very small glass objects about the size of a die, according to the ETH Zurich researchers. However, Masania said still believe they achieved the goal of the project, which was to prove that 3D printing can be used to produce complex glass objects, no matter what the limitation is currently.

Masania said his team has applied for a patent for their technology and is currently lining up commercial partnership with a Swiss glassware dealer.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco and New York City. In her free time she enjoys surfing, traveling, music, yoga and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like