March 22, 2010

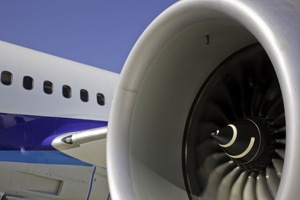

Materials used to make components for the next generation of lighter andhigher performing jet engines will include anew, less-expensive superalloy.

ATI 718Plus alloy is the firstnickel-based superalloy to be used for both static and rotating jet enginecomponents in more than 40 years, according to Allegheny Technologies Inc. ofPittsburgh. It's going into commercial production this year.

The superalloy is described as a workable, formable replacement materialfor engine structures such as turbine cases, blades and shafts. Fasteners arealso potential applications. Heat treatment consists of solution treatingfollowed by a double aging treatment. Different heat treatments are useddepending on the mechanical properties desired.

The material can be welded in both the solution-treated and fully agedconditions using inert gas-shielded arc, plasma arc, electron beam andresistance-welding techniques.

"ATI 718Plus alloy plays an important role in helping enginemanufacturers meet their aggressive goals for fuel efficiency and emissionswhile providing as much as a 25-percent reduction in part cost over moreexpensive nickel-based superalloys," says Rich Jeniski, director, marketing andbusiness development at ATI Allvac.

ATI says ATI 718Plus alloy provides a major performance advantageover standard alloy 718: a higher operating range that will function reliablyat temperatures 100F hotter. Its cost advantage derives both from lower rawmaterials' costs as well as improved manufacturability.

New jet engines are more efficient because of higher operatingtemperatures. The hot gas path can be increased from 1200F to 1300F, requiringhigher-performing components. Emissions are also reduced because the combustioncycle is more complete.

Another alloy used in the new jet engines is a gamma titanium aluminidematerial supplied by ATI Wah Chang. It's used in the low-pressure section ofthe GEnx engine that will power the Boeing 787 Dreamliner. It is said to havehalf the weight of nickel-based alloys, but is able to withstand higheroperating temperatures, further extending fuel efficiency.

It's not specifically known if ATI 718Plus is used in engines designedfor the 787 Dreamliner. However, Rolls-Royce, one of the Dreamliner enginesuppliers, extensively tested ATI 718Plus at Rolls Royce Deutschland, whichestablished an evaluation and optimization program for the alloy. The programincluded the development of a complete processing route as well as substantialmechanical testing.

Allvac 718Plus alloy is available in mill product forms for end-useapplications that also include forging and extrusion dies.

New Nickel-Based Superalloy Targets Jet Engines A

About the Author(s)

You May Also Like