Join a free online course, June 28-30, about one of the most important topics to understand when you’re making something -- which materials make sense, why, and in which situations.

June 22, 2016

Materials Really Matter! In fact, in my opinion it’s safe to say that materials matter more than anything in product development.

Humans have been making things for thousands of years and have developed countless great methods of producing high-quality products. 3D printing has been added to this list in the last 30 years, and has recently exploded into our inboxes and web browsers, as news of life-changing breakthroughs pop up every day. Unlike many other really exciting technologies that come (and go), 3D printing demonstrates a unique ability to do things that really change people’s lives. And so we embrace its coolness with an excitement and fervor rarely seen in a generation. However, it’s easy to get caught in the vortex, to believe that it will change everything in product development, in manufacturing for that matter.

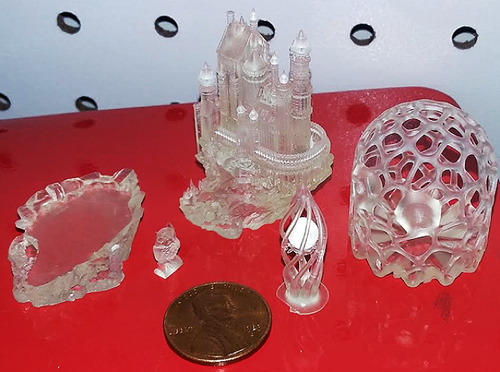

With 3D printing we can make incredibly complex objects -- jewelry, devices, and gadgets of all sorts. But the real challenge is faced head-on when you try to put a 3D-printed object to a test of real usability. It’s relatively easy to make things look, feel, and fit as they should, but can they perform like they’re supposed to? It all comes down to materials. It turns out that 3D printing really is quite limited to date in its ability to create products that perform as expected. In fact, every consultant in the 3D printing market says materials are the most important factor throttling the growth of this amazing technology. And it is in no way a replacement for good old machining and mold-making, and the countless other manufacturing methods that have buttressed innovation in product development for centuries.

From June 28-30 I’m teaching a free online course that’s only 45 minutes per day about one of the most important topics to understand when you’re making something -- which materials make sense, why, and in which situations. There are so many complex factors affecting many tough decisions. And no single answer works for very many situations, all the time.

About four years ago I founded a 3D printing lab for our community. With more than 1,850 users through our lab last year, it is obvious that 3D printing is truly amazing. And we have learned its limitations, which I’ll share with you during the class. I’ll start out with a comprehensive look at the wide range of popular metals, plastics, and polymeric materials that are used in 3D printing, CNC machining and injection molding. I’ll give you some clear, concise guidelines to help in your material selection process. Then I’ll get down to the details. I’ll discuss the various behaviors and properties of common materials along with key factors that should guide your material selection process. In the third session, I’ll discuss the impact of material choices on many of the core business processes in discrete manufacturing.

I look forward to presenting this material to you. I’ve been deeply involved in 3D technology and product development for more than 35 years. In this time, I’ve seen many technology cycles come and go, and many great products with them. Today, in our biomaterials research lab at Colorado State University, I see every day the impact of materials choices on some of the toughest problems, and some of the most complex products that we humans have come to develop. Materials is an exciting field, where we can continue to make huge impacts on people’s lives, and it all starts with the right material for the job.

Material choices can spell success or failure of product development and innovation -- indeed to the core of business itself. To join me in this course, register here. I’ll be answering your questions after my presentation each day and I’d like to learn from your experiences. If you can’t make the live classes, register anyway because they’ll be available in archive and you can attend at your convenience.

[images via David Prawel]

David Prawel, PhD, is founder and president of Longview Advisors Inc., director of Idea-2-Product 3D Printing Laboratory, and associate director of the Biomaterials Research & Engineering Laboratory at Colorado State University.

About the Author(s)

You May Also Like