August 26, 2015

True originality is not often a priority when creating a new product. Design engineers would rather borrow from existing designs. Think of the similarity in design elements and functionality in Apple products introduced over the past 15 years. The reasoning is simiple: resuing design speeds time-to-market, reduces validation efforts, and sustains the overall look and feel of the brand.

“If you’re in a regulated industry like aerospace, creating a new part can cost tens of thousands of dollars,” Kurt Lundstedt, product portfolio manager at Dassault Systèmes, told Design News. “If you can identify duplicate or re-used information, it reduces the costs and gives you more buying power.”

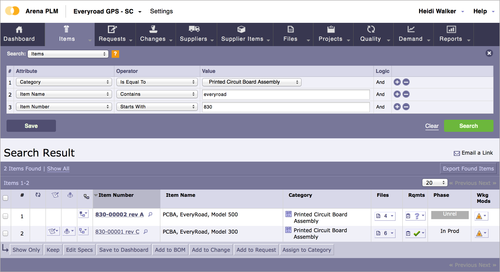

Mining previous designs lets the design engineer aggregate parts purchasing. Specifying a part that is already used in a number of other products can drive down costs significantly. “When a new product comes to market, the cost of a component might be five times what it would be in volume,” Steve Chalgren, EVP and chief strategy officer at Arena Solutions, told Design News. “Getting the cost down can be a matter of finding the volume for cost reduction. That can drop the price of a product from $500 to $100.”

Parts and Assemblies Are Pre-validated

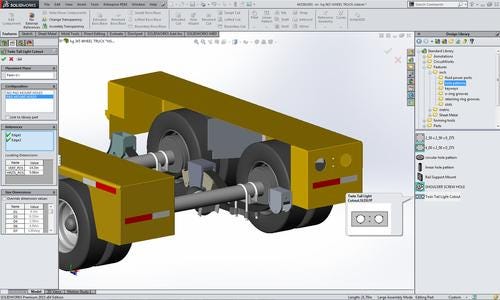

Martin Neumüller, director of product management at PTC, said that design engineers have to ask questions such as: Is there a part that can be duplicated? Can some mechanical or requirement aspects of a part be reused? Can some of the electronics or some of the software be reused?

“You can use PLM or CAD tools to leverage existing designs that may have a highly complex surface with complex mathematics,” Neumüller said. “You can reuse the geometric as well as the IP of existing designs.”

MORE FROM DESIGN NEWS: Which Engineering Disciplines Have the Most Job Openings?

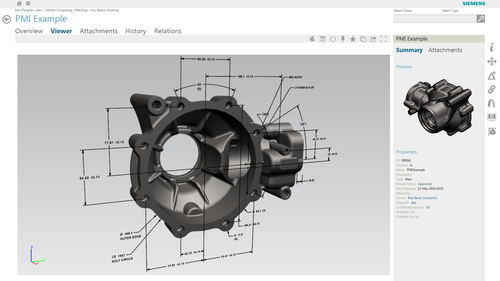

Reusing existing parts or assemblies reduces the time involved in validation, whether it’s identifying conflict materials or putting the part through quality trials. “There’s the whole time and cost savings that come from reuse, but also the ability to reuse proven concepts,” Dennis George, marketing manager at Siemens PLM, said. “There’s the whole process of running this design through quality assurance. If you’ve had the existing part on the road for a couple years and it works, and if you have no warrantee issues with it, then you don’t have to re-verify it.”

Reuse as a Branding Tool

Reusing existing designs can actually enhance brand identity. Some companies gather elements of their products on a website to make it easy to reuse positive elements of their products. “They create a living style guide that showcases the different fonts, line-heights, grids, colors, and animations that are part of the digital brand guidelines. The guide is represented in code that backs up the branding,” Courtney Hemphill, partner and technical lead at design firm Carbon Five, said. “It becomes an ecosystem where they can pull HTML, CSS and Javascript to use directly in other digital products.”

Hemphill said that it doesn’t take a large company to maintain an easy-to-access collection of available pre-used design elements. “Even smaller companies see that design standards are not just creating efficiency, but also offering fidelity to the company brand, voice, and vision.”

In Search of the Old

A major challenge for design reuse is finding similar parts or assemblies. Design software vendors have turned to consumer search tools to navigate existing designs. “Engineers are accustomed to searching on Google to find things. They carry that forward into their work life, doing web-based searches with filters,” said George from Siemens PLM. “We’ve added a Google-based, web-based tool to filter through the results that come back from the search criteria.” George noted that if you’re searching for a grill shutter, you can bring it up on the screen as though you were shopping on Amazon or Home Depot. “You can look at the shutters side-by-side. It’s a matter of presenting the right information to the user in a way that is meaningful.”

Another challenge is the wide spectrum of files that may contain previous designs or design elements. Advanced search can cut across disparate systems. “We offer advanced search beyond file names and locations. Our search tool indexes the shape of a part,” said Lundstedt from Dassault Systèmes. “It could be in different file systems. The results will say, ‘Here are 10 parts that are 98 percent similar. It’s already in the system with a part number, a source, and the cost.’”

MORE FROM DESIGN NEWS: Suppliers Are Joining the Design Team

But not all engineers think in conventional language, and nor do they necessarily index by keywords. Thus, geometry can also be a unifying indexing factor. “We see more and more discussions and comments related to geometric search. Designers are creating their models by searching for similar shapes,” said Neumüller from PTC. He noted that one of the hurdles is “find-ability.” The user may not think to search through a database system to find a potential model or a part that would fit, so PTC provides tools that can seek a specific geometry in different file systems.

For reuse to truly be efficient, the design engineer needs to know the details of the reused part’s design process. “When you find a part, you also need to know all of the decisions that went into it. You need to know the tradeoffs that went into the design,” George said. “You can attach notes to designs that explain why you made the decisions. Future users will know how it applies and will understand what might happen if they make changes. It’s the reuse of requirements, not just design.”

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine, Chile Pepper.

About the Author(s)

You May Also Like