July 5, 2013

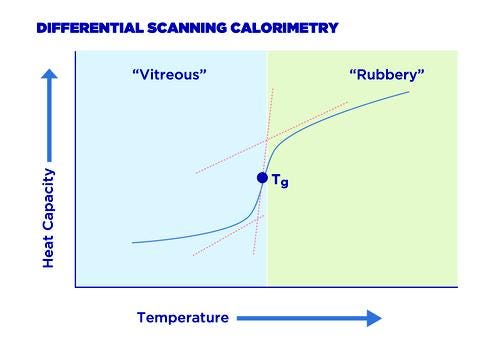

Changes in temperature can have an enormous impact on the performance properties of epoxies and other thermosetting polymer systems. Prior to curing, an epoxy consists of a resin and a curing agent. When polymerization occurs, the entity becomes an organized crystalline type structure in what is sometimes referred to as a glassy state. In this state, the molecules are able to vibrate but are otherwise locked in place. As the temperature rises, the molecules are able to move more freely, and the material gradually starts to soften. As the temperature continues to rise, the polymer eventually experiences a profound state change to a more pliable, rubbery state.

Though this state transition takes place gradually over a range of temperatures, the glass transition temperature range (Tg) is often designated by a specific temperature. The actual glass transition temperature range depends on the molecular structure of the material, the testing method, sample preparation, the cure schedule, and the degree of cure.

Epoxy properties change with increases in temperature

As the temperature increases, thermosetting polymers exhibit changes in their physical properties, including tensile strength, thermal expansion, heat capacity, modulus, and electrical properties. One significant change is that of the linear coefficient of thermal expansion (CTE). The CTE quantifies how much a material expands or contracts during temperature excursions; the higher the CTE, the more the material will expand or contract with temperature excursions.

As a material moves through the glass transition temperature range, its CTE increases dramatically -- ultimately becoming three to five times higher than its value below the Tg range. After the epoxy passes through the glass transition temperature range, its material properties change significantly. These changes are not necessarily permanent; they depend on the duration and extent to which the Tg range is exceeded. Brief excursions above that range will not irrevocably damage the material. As an epoxy returns to ambient temperatures, its strength profile is typically restored.

It is important that design engineers understand the nature of this transition, so that they can choose the best system for a specific application.

About the Author(s)

You May Also Like