June 13, 2012

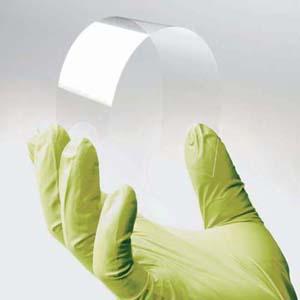

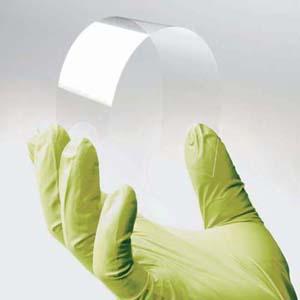

On the heels of Plastic Logic's announcement of a flexible color display for e-readers (which we covered last week), Corning has released Willow Glass, a display material that is 100 microns thin and flexible enough to be rolled.

Willow Glass is said to be the first display material that can be adapted to high-volume, low-cost, continuous roll-to-roll manufacturing processes. (You can watch a video from Corning at the bottom of this post.) These processes, similar to the methods used for printing newspapers, involve temperatures of up to 500 degrees Centigrade, which the polymer films used in plastic display technology can't tolerate.

The glass is being produced in a sheet-to-sheet manufacturing process. Switching to roll processing will be "a long-awaited industry milestone," Dipak Chowdhury, division vice president and Willow Glass program director, said in a press release. Corning is collaborating with customers, research institutions, and equipment makers to develop an optimized process design and compatible process equipment.

Corning plans initially to target Willow Glass for OEMs developing display and touch applications. Its thinness, strength, and flexibility would let displays be wrapped around devices such as medical equipment or around structures such as signage. The company is working on other applications, such as lighting and solar cells.

Willow Glass can be used to support color filters and thinner backplanes for organic LEDs and LCDs in high-performance portable electronics such as notebook computers, tablets, and smartphones. It can also help engineers developing conformable displays designed for nonflat surfaces or for immersive viewing.

Corning says the material is formulated to perform well for electronic components such as touch sensors, and it leverages the natural hermetic properties of glass to serve as a seal for OLED displays and other moisture- and oxygen-sensitive technologies. Even at 100 microns, it can hermetically seal components while providing excellent surface, thermal and optical properties, the company says.

Like its predecessors, Gorilla Glass, EAGLE XG Slim, and Corning Lotus Glass, the new material is produced with Corning's proprietary fusion process.

Related posts:

About the Author(s)

You May Also Like