February 23, 2009

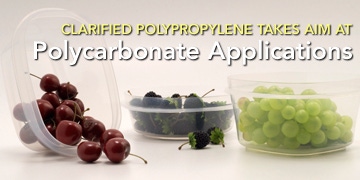

A new highly clarified polypropylene is taking dead aim atpolycarbonate in applications where design engineers are concerned aboutpotential health effects of bisphenol A (BPA) feedstock.

HomeConcepts Products of Vernon,CA recently switched two containers made of polycarbonate to polypropyleneclarified with Millad NX8000, a new additive that reduces haze in PP 50 percentcompared to the previous industry standard. Other major food containersuppliers are also in the midst of review of possible PC replacements.

"With the high clarity imparted by Millad NX8000, we achieved thesee-through visibility that's so important in food storage products. In fact,leftovers never looked so good. At the same time, we were able to addressconsumer concerns regarding health and safety and environmental responsibility.This initiative with Milliken also helped Home Concepts Products achieve itsgoal of becoming a BPA-free company in 2009," said Michael Moghavem, CEO ofHome Concepts Products.

Clarified PP also saves money compared to polycarbonate, in part becauseit's one-third less dense than PC. Prices for injection grades of PC run around$1.70/lb versus 40 cents/lb for neat PP. The cost of clarified PP is about halfthe cost of polycarbonate.

Traditionally, PC has offered a more upscalelook, plus rigidity and durability compared to a soft feel for PP. Publicityabout possible healthrisks with the BPA components of polycarbonate, particularly in babybottles, has scared many consumers away from the material. Websites have even popped up alerting consumers to products that do and don'tcontain BPA.

This is Tupperware's official positionon BPA: "On the strength of the repeated governmental scrutiny thatpolycarbonate has had, Tupperware continues to believe the material is safe.However, as Tupperware has the highest regard for the safety of the consumersof its products and the functionality of these products, it will continue toclosely monitor this scientific debate and research the best materials for usein its products."

Tupperware no longer uses polycarbonate for anychildren's products, including baby bottles sold in the United States ofCanada. Polycarbonate is still used in a small percentage of the company's products,primarily those intended for high heat resistance, as well as some serving lines.Rubbermaidalso offers BPA-free and polycarbonate products.

According to Brian Burkhart, global marketing manager for Milladclarifying agent, polypropylene can withstand heat, and is even being used inbaby bottles, which are often warmed in pans of water. "One of the keyattributes of polypropylene is that it is hot fillable," he said in aninterview with Design News. The heat deflection temperature of homopolymer PPat 66 psi is 221F. Some other clear plastics lack adequate HDT, and even wiltin a dishwasher.

There is also potential for highly clarified polypropylenein several medical applications, such as syringe barrels, petri dishes andhousings for medical equipment. "Options are limited only by people's abilityto make use of it," says Burkhart. "Over time, I hope people will see this as anew material and start to design around it because it really wasn't an optionin the past."

One example he offers: "We had a customer at one time whotold me they had a specification in their design limitations that said if athickness was above a certain dimension (2 mm), we wouldn't use PP. When weshowed them this material they got very excited and said we can change thatspecification to a different number now."

Another environmental factor, says Milliken's Burkhart, isthe recyclability of polypropylene. "It goes right in with the otherpolyolefins in many towns," he says. Many automotive engineers are also movingto polyolefins for car interiors to improve their recyclability. Olefins suchas milk bottles and PP containers have similar densities and are removedthrough recycling streams with the same process.

Clarified Polypropylene Takes Aim at Polycarbonate Applications A

About the Author(s)

You May Also Like