Biomimicry is a popular research method these days, in particular in the quest for more environmentally friendly and sustainable materials. Researchers at MIT are among the latest to use biomimicry in this endeavor, with a new biologically inspired design of the world’s most common building material -- concrete.

June 9, 2016

Biomimicry -- the use of nature to inspire design -- is a popular research method these days, in particular in the quest for more environmentally friendly and sustainable materials. Researchers at MIT are among the latest to use biomimicry in this endeavor, with a new biologically inspired design of the world’s most common building material -- concrete.

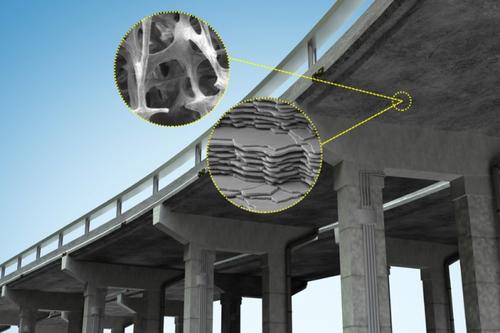

A team in MIT’s Department of Civil and Environmental Engineering (CEE) have proposed a new way to build cement paste -- the binding ingredient in the material known generally as cement -- by examining the structure and properties of natural materials such as bones, shells, and deep-sea sponges. Researchers chose these materials because of their exceptional strength and durability, which are the prime reasons concrete is such an often-used construction material, they said.

Researchers at MIT have used the strength and durability properties of bone, shells and sea sponges to come up with a design for a more sustainable version of concrete. The design takes a bottoms-up approach similar to what’s found in those materials, which use precisely assembled yet simple building blocks to achieve the desired affect.

(Source: MIT)

However, while concrete is ideal for building because of these qualities, it also poses a great harm to the environment, said PhD candidate Steven Palkovic, who worked on the project and co-authored a paper that researchers published in the journal, Construction and Building Materials. This is what inspired the team to seek more natural alternatives for a concrete formula, he said.

“Concrete poses an ongoing challenge in sustainability for researchers and engineers,” he told Design News. “The production of one of the main ingredients in concrete, Portland cement, currently accounts for 5% to 7% of global greenhouse gas emissions. An alternative formula for concrete that replaces Portland cement with locally available additives provides a low-cost and high-impact solution for improving the environmental footprint of the construction industry.”

What makes the natural materials examined in the research so strong and durable is their precise assembly of structures at multiple length scales, from the molecular to the macro, or visible, level. For example, they found that a deep-sea sponge has an onion-like structure of silica layers that provides a mechanism for preventing cracks. They came up with their design by examining aspects like this of the various materials in an attempt to adopt a similar bottom-up, building-block approach to building an alternative material, Palkovic said.

“Natural materials like shells and bones achieve incredible mechanical performance through the arrangement of simple building blocks into larger hierarchical structures,” he said. “In our paper, we propose a similar approach where we abstract the fundamental components of concrete into simple building blocks which change with the inclusion of additives. We can use computation to understand how these building blocks then affect material performance to progress toward performance-based design.”

READ MORE ARTICLES ON BIOMIMICRY:

Ultimately, the team hopes to identify materials in nature that may be used as sustainable and longer-lasting alternatives to Portland cement, which requires a huge amount of energy to manufacture, they said. The resulting material can be used in the same way as concrete while offering “improved material performance with a lower environmental impact, Palkovic said.

Materials being eyed as additives for the concrete alternative include volcanic ash from Saudi Arabia, which researchers are using as part of the Kuwait-MIT Signature Project, he said, explaining further how the ash is being used by researchers:

“This material is a suitable additive because of its geographic proximity to Kuwait and reactive nature with existing concrete ingredients. We then design an optimum mix by studying the affect of particle size, volume fraction, and water-to-cement ratio. However, we believe that our approach is flexible and suitable for evaluating the suitability and optimization of any locally available additive.

While researchers at this stage of their work have focused on the nanometer and micrometer structure of cement paste, they will broaden their scope later to understand its influence at the macroscale on the order of millimeters to centimeters to make way for the use of other sustainable materials that can be used to replace it, Palkovic said.

“The macroscale is where engineering design properties like strength and fracture resistance are measured through traditional laboratory experiments,” he explained. “Ultimately, we want to utilize our framework to investigate the suitability and design of many sustainable additives and connect the behavior of cement paste with the concrete composite that make up our buildings and bridges.”

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 15 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like