May 22, 2012

A tough new bone scaffold material invented by Tufts University engineers uses micron-sized silk fibers to reinforce a silk fiber matrix. The composite material is the first all-polymeric bone scaffold material to provide enough temporary mechanical support during repair, and is the first that is fully biodegradable.

Biomedical engineers at the Tufts School of Engineering say the new technology could improve repair methods for bones and other tissues after patients experience accidents or disease. Some all-polymeric biomaterials, such as collagen, are used for bone regeneration, but they don't have enough compressive strength. Attempts to include ceramic or metal materials in polymers can achieve the goal of improving mechanical properties, but these composites often make bone remodeling and regeneration difficult or impossible.

Grafts made of natural human bones can be used, since they withstand a high degree of pressure and are hard, yet are light in weight. They are also elastic enough to stand up to a moderate amount of torsion. In addition, the interior of human bone consists of a matrix structure that helps foster the growth of bone cells and which is easy for them to adhere to.

But human bone grafting is problematic. The amount of human bone taken from the patient is limited and requires additional surgery. Taking bone from donors is risky because of possible disease or rejection.

The silk microfiber-protein composite matrices mimic the mechanical features of native bone. These include the stiffness of bone's interior matrix and the surface roughness that enable differentiation of human mesenchymal stem cells from bone marrow to achieve bone formation. The team found that, combined with the inherent strength of silk fibers, the compressive properties inside the scaffolds were enhanced by the structure's compact fiber reinforcement.

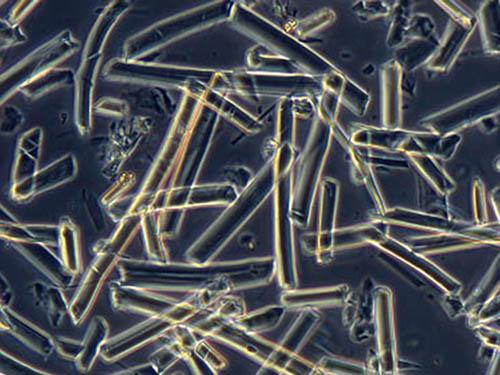

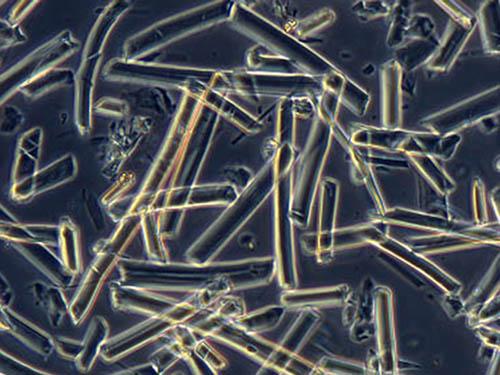

To manufacture the silk microfibers, the Tufts researchers applied alkaline hydrolysis, which uses alkali chemicals to break down complex molecules into their building blocks. This method cut down on the time and cost required to make microfibers in a variety of sizes, compared to conventional processing methods for creating silk microfibers.

The Tufts bioengineers' silk composite material has a high compressive strength of 13 MPa in a hydrated state. Compressive strength, surface roughness, and porosity are tunable, depending on the length of the fibers. Although the values achieved are an overall improvement, they are still less than those for human bone. The researchers said that such scaffolds can be used as temporary biodegradable support while a patient's native cells are grown.

Related posts:

About the Author(s)

You May Also Like