June 3, 2015

New glass coating, the design of which was inspired by two disparate examples in nature -- a moth's eye and lotus leaf -- could mean significant improvements for solar panels, lenses, military equipment, windows, and other products in the future, thanks to the Department of Energy.

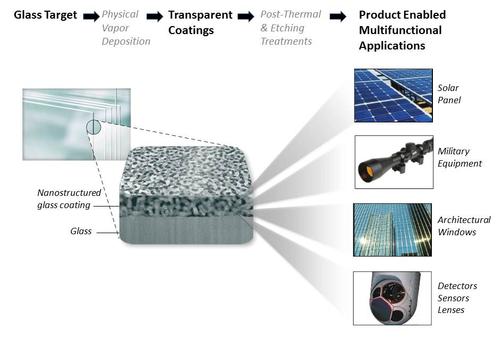

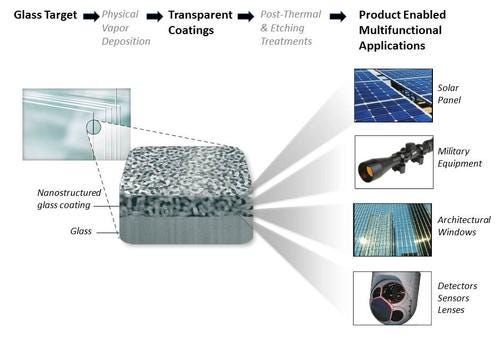

Researchers at the department's Oak Ridge National Laboratory (ORNL) have developed an anti-reflective and water-repelling -- also known as superhydrophobic -- glass coating based on a nanostructured layer of porous glass film. Inspiration for the design of the glass came from the way lotus leaves repel water and self-clean when it rains, and the anti-reflective nature of moth's eyes, Tolga Aytug, a researcher who worked on the design and member of ORNL's Materials Chemistry Group, told Design News.

Aytug explained how it's been traditionally difficult to achieve the design of durable, transparent glass that is superhydrophobic with both high optical quality and mechanical durability that also can be produced with any scale or uniformity.

MORE FROM DESIGN NEWS: Researchers Make Breakthrough in Capturing, Storing Solar Energy

"Traditional superhydrophobic coatings are soft in nature, with a Teflon-like surface chemistry, which results in reduced adhesion and durability, and hence such coatings are not suitable for robust applications," he told us.

The marketplace, however, demands optical transparency and durability, and the ORNL team found inspiration in nature to develop a coating that can make glass self-cleaning and antireflective. "These natural structures are mimicked by creating a coating that is based on nanostructured single-layer of porous glass films," Aytug said.

Aytug went on to explain how the glass was fabricated, beginning with the deposition of a glass coating using a sputter target made from a borosilicate glass composition, a procedure that ensures metastable phase separation into a spinodal -- that is, a non-nucleation, continuous phase separation -- pattern when the coating is properly thermally processed.

MORE FROM DESIGN NEWS: Robotic Eel Tapped to Explore Jupiter's Oceans

"Following film deposition, the subsequent heat treatment renders the glass coating phase separated into an interpenetrating pattern consisting of alkali-borate-rich and a silica-rich phases, the former being relatively more soluble by a variety of chemicals," he explained. "Next, a controlled level of differential etching is employed to selectively dissolve the sodium-borate-rich phase, leaving behind a porous nanoscale three-dimensional reticulated network of high-silica content glass phase."

To be superhydrophobic, a surface must achieve an angle of water droplet contact exceeding 150 degrees. ORNL's coating has a contact angle of between 155 and 165 degrees, so water actually bounces off, carrying with it dust and dirt, Aytug said. This is a significantly attractive quality for optical applications in particular, especially when combined with the coating's suppression of light reflection, he said.

The coating also has significant benefit for the operational efficiency of PV modules, he said, enhancing their operational efficiency by coupling more light into solar cells, he said. They also can substantially reduce the maintenance and operating costs by preventing the panels from building up contaminants on their surface, maximizing the potential for converting sun into electricity.

MORE FROM DESIGN NEWS: How Biomimicry Is Having an Impact on Sustainable Design

Aytug and the research team continue to work on optimizing the coating by developing chemical vapor deposition routes for its production. They also are looking to license the technology to large glass manufacturers, he told us.

More information about the research can be found in a paper published in the Journal of Materials Chemistry C entitled "Monolithic Graded-Refractive-Index Glass-based Antireflective Coatings: Broadband/Omnidirectional Light Harvesting and Self-Cleaning Characteristics," of which Aytug is the lead author.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 15 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

Atlantic Design & Manufacturing, the largest advanced design and manufacturing trade show serving the Northeastern US, will take place in New York, June 9-11, 2015. It's your chance to meet qualified suppliers, get hands-on with the latest technologies, and expand your network. Learn more here.

About the Author(s)

You May Also Like