Data and video give users quantitative and visual information on the status of equipment.

May 1, 2017

A pair of start-ups are teaming to deliver simple, cloud-based sensor intelligence and video surveillance to applications ranging from food processing and transportation to restaurants and factories.

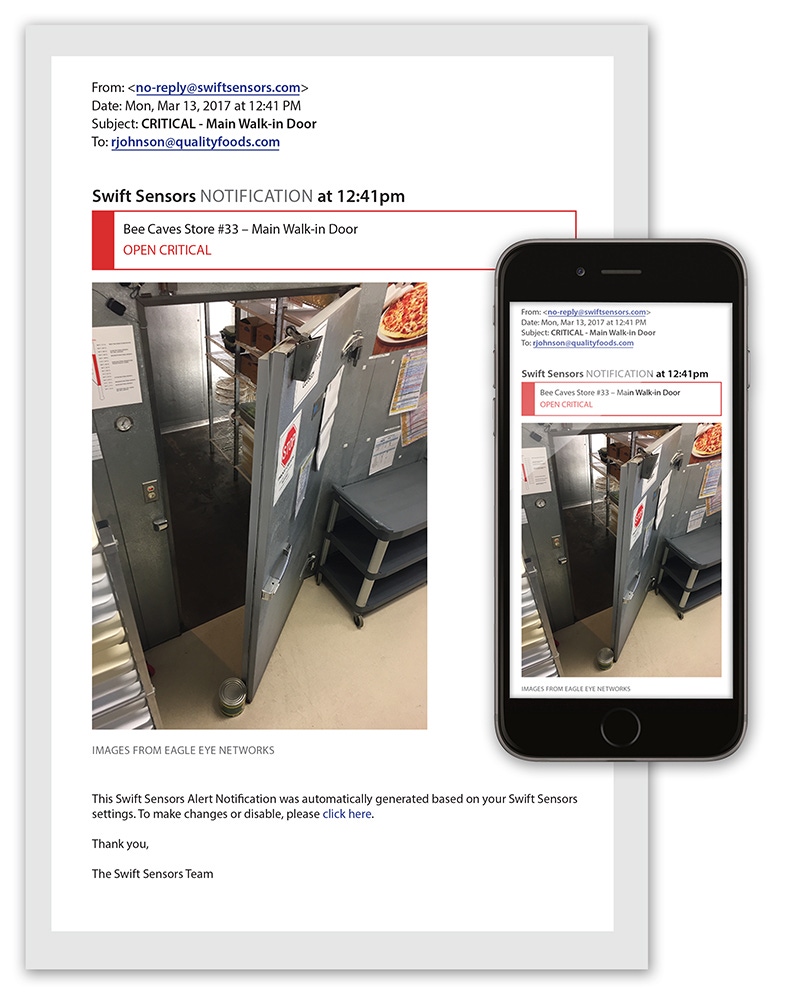

Swift Sensors, Inc. and Eagle Eye Networks, Inc. want to bring a one-two punch to businesses, enabling them to monitor equipment via both sensor data and video, and do it without the need for programming. “The whole purpose is to give our customers a much quicker understanding of the root cause of a problem,” Ray Almgren, chief marketing officer for Swift Sensors, told Design News. “Instead of just sending a notification that says, ‘It’s 45° in your cooler,’ this could give them a snapshot that tells the them the cooler door is open.”

|

A pizza restaurant in Austin, TX, uses video alerts on an IpHone to remotely check the status of its walk-in freezer. (Source: Swift Sensors, Inc.) |

The two companies hope to accomplish that with a clear division of labor. Swift Sensors makes matchbox-sized sensor packages for monitoring temperature, humidity, vibration, motion, activity, location, voltage and electrical current in equipment. Eagle Eye Networks makes camera-based network sensing. Together, the two aim to provide information to engineers and business owners about the status of their remote machinery. Customers can receive synchronized alerts that give them, not only data, but a video snapshot of the machine in question.

The two companies are teaming on a beta application at a pizza restaurant, Papa Murphy’s, in the Austin, TX, area. There, temperature sensors provide status of the restaurant’s walk-in freezer, while the video lets the owners know if the cooler door is open.

Their technique is a departure from conventional sensing methodologies in two respects: first, data and video are sent directly to the cloud; second, the system requires no programming skills or technical expertise. During set up, sensors automatically find a sensor bridge that securely communicates with the cloud, and the cloud-based software, in turn, sends information to customers. The two companies say that non-technical users can outfit an entire application and be looking at data and video inside of one hour.

“The idea is to take advantage of IoT technologies to enable a quick response,” Almgren told us.

Swift Sensors announced the sensor capability in 2016. It has since engaged in applications with Kraft Heinz Co. in Champaign, IL, as well as with Sysco Foods and McDonald’s. Earlier this week, it said it was teaming with Eagle Eye to do enhanced video notifications. The two link the video and data through a specially-designed application program interface (API). Known as a “restful” API, it uses HTTP to request and post data, so that when a user receives a sensor notification, the API finds a synchronized video snapshot and sends that, as well.

Almgren said that the company is working with users who don’t have sensor background, as well as engineers who understand networking but just don’t want to invest their time and effort in low-level coding.

“This is a substantially simplified way of monitoring temperature, pressure and video in a facility,” he told us. “All you have to do is turn on the sensors and connect them to the bridge, and they start communicating.”

Senior technical editor Chuck Murray has been writing about technology for 33 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and autos.

The future is now at ESC Boston. VR, augmented reality, sensors, embedded speech, artificial intelligence and machine learning are already reshaping the tech landscape. Learn how these innovations will impact your work at the Embedded Systems Conference’s new Advanced Technologies track May 3-4. Register today.

About the Author(s)

You May Also Like