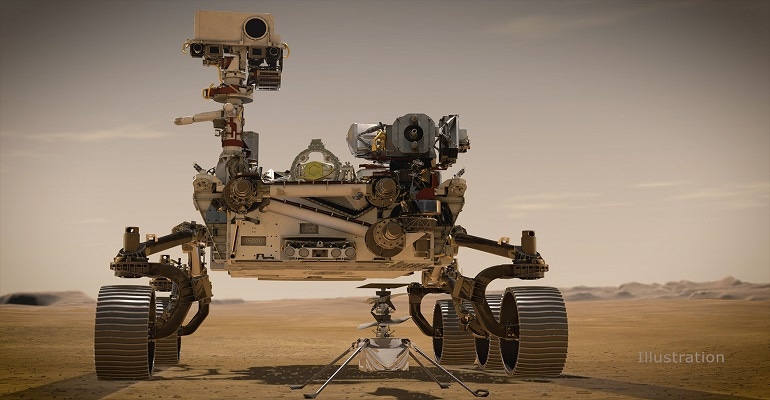

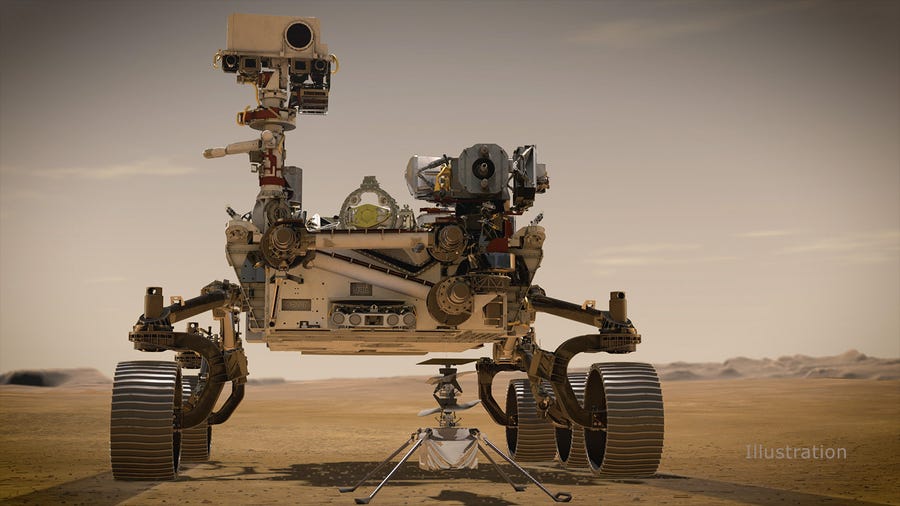

The Perseverance rover is searching for signs of life on Mars. It’s also taking along the Ingenuity helicopter to try flying in the Martian atmosphere.

July 30, 2020

NASA's Mars 2020 Perseverance rover is heading to the Red Planet to search for signs of ancient life. The rover will collect samples for a future return trip to Earth. The ultimate goal is to pave the way for human exploration. The rover will carry several technology demonstrations including the Ingenuity helicopter, which will attempt the first powered flight on another planet. Perseverance has a new set of science instruments and the ability to “self-drive” on the Martian surface.

The Mars 2020 mission with its Perseverance rover is part of NASA's Mars Exploration Program, a long-term effort of robotic exploration of the Red Planet. The Mars 2020 mission addresses high-priority science goals for Mars exploration, including key Astrobiology questions about the potential for life on Mars. The mission takes the next step by not only seeking signs of habitable conditions on Mars in the ancient past, but also searching for signs of past microbial life itself.

The Perseverance rover introduces a drill that can collect core samples of the most promising rocks and soils and set them aside in a "cache" on the surface of Mars. A future mission could potentially return these samples to Earth. That would help scientists study the samples in laboratories with special room-sized equipment that would be too large to take to Mars.

The mission also provides opportunities to gather knowledge and demonstrate technologies that address the challenges of future human expeditions to Mars. These include testing a method for producing oxygen from the Martian atmosphere, identifying other resources (such as subsurface water), improving landing techniques, and characterizing weather, dust, and other potential environmental conditions that could affect future astronauts living and working on Mars.

Perseverance Will Retrieve Core Samples to Seek Signs of Life

The Perseverance has a number of goals during this mission, but most of them include looking for life and preparing for future visits, including visits by humans. “We have a slew of goals. We want to get insights into how earth developed, get core samples from Mars, and bring them back to earth,” Mo Abid, deputy chief mechanical engineer and manager of the Mechatronics group at JP, told Design News. “The famous Ingenuity helicopter will fly in the atmosphere to see how successful we can get at doing that. But the mail pillar is to study past life on Mars and see how it evolved.”

While the new rover may not look much different from earlier rovers, there are some qualitative alterations. “The Perseverance looks similar to the Curiosity rover, and the way we’re going to land is similar. The difference is the energy harvesting is not like the solar panels on the previous rovers,” said Abid. “Also, it’s different in its mobility – how we drive and the wheel we use. The wheel we used before had issues. We changed the design of the wheels to account for that.”

Abid also noted that the drilling this time will be different. “Our approach this time is to drill into rocks to get core samples. We’ll bring samples to the rover and get them hermetically sealed. In principle, we will load them into rockets and launch them from the surface of Mars of later trips,” said Abid.

One of the most challenging part of preparing for this mission was making sure the containers for the core samples were free from Earth particles. “Because we’re going to collect samples, they need to be pristine. We need to make sure we don’t take earth contaminants and contaminate the samples,” said Abid. “The tubes are the the cleanest piece of hardware we create on earth. We have to make sure we don’t take anything from earth that would contaminate it downstream.”

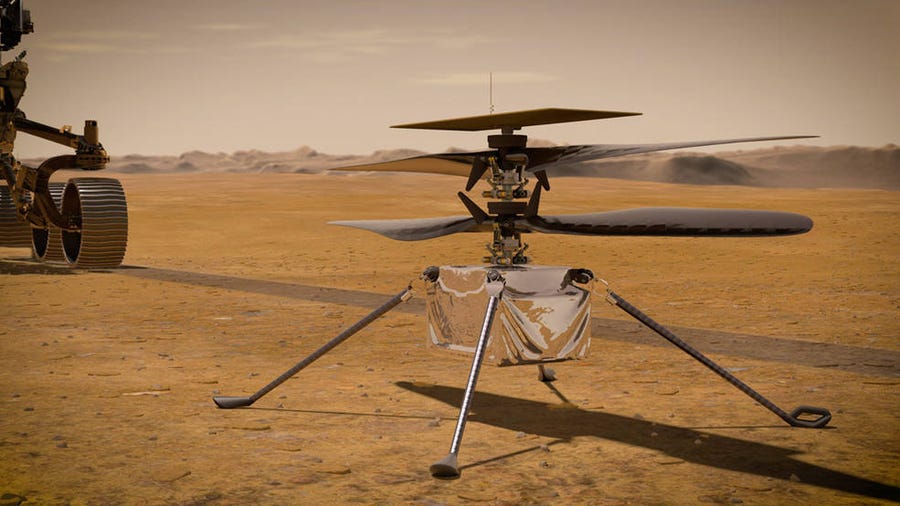

Ingenuity Will Fly the Surface of Mars

One particularly interesting part of the Perseverance mission is the ingenuity helicopter. “One of the most exciting parts of this mission will be the actual flight test of the Ingenuity helicopter. We will do the flight experiments over 30 Martian days,” Teddy Tzanetos, flight test conductor for the Ingenuity helicopter at JPL, told Design News. There are thermal considerations. We’re going during the warmer part of the year. In winter we would not be able to store enough charge in the batteries to survive the night.”

The overall goal for Ingenuity is simple to prove it can actually fly in the Martian atmosphere. “Our mission is a technology demonstrator. We have no payloads on the helicopter. The whole point is to prove we can fly,” said Tzanetos. “We will do five flights in those 30 days. We’ll use solar power to charge, but the energy demands will change of the years. We did a lot of simulation, from aerodynamics to controls. But simulation can only get you so far. We need verification and test. After that first flight, we’ll go out partying.”

A Mix of Ruggedized and COTS Parts

Interestingly, many of the parts that make up Perseverance and Ingenuity come right off the commercial shelf. “We try to see if we can use COTS items. The helicopter uses off the shelf parts. For Perseverance we’re using more unique parts created for Mars,” said Abid. “We use highly mechanized parts. The difficulty for using parts or processes is the cleanness requirements. We have to eliminate any spores that you find in the coatings and polishing of parts. Because we have tight examination requirements, we tailor them so it’s not direct off the shelf.”

One supplier to the Mars vehicles provided a combination of COTS and uniquely designed parts. “They are certainly one-offs, but many of the core components in the motor and gearbox are the same as those used in the standard industrial productions. That includes stators, windings, magnets and gear teeth,” Robin Phillips, head of the maxon SpaceLab told Design News. “We did additional inspections to ensure that every single part was perfectly built.”

Maxon took parts from its standard toolbox and then augmented them for use on Mars. “Maxon provided motors and gearboxes that are based on COTS industrial solutions but are heavily modified for compatibility with high vibration, shock and wide temperature range environments.,” said Phillips. “For example, a rotor might be glued to bearings in an industrial design but is secured with additional pressed and welded rings in a space version since otherwise the shocks during launch would break the adhesive bond.”

Over the course of his work with JPL on the Mars vehicles, Phillips gained a profound respect for the quality of NASA’s engineering. “What an amazing depth of technical knowledge that the JPL engineers have. In particular how the space environment can uncover design weaknesses that would never have any effect on an Earth-based application but can cause motor – and hence mission failure – on Mars,” said Phillips. “The collaboration between the JPL and maxon teams was essential to combine our decades of experience in designing motors and gearboxes with JPL's decades of experience in designing mechanisms for spacecraft.”

Rob Spiegel has covered automation and control for 19 years, 17 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years, he was owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like