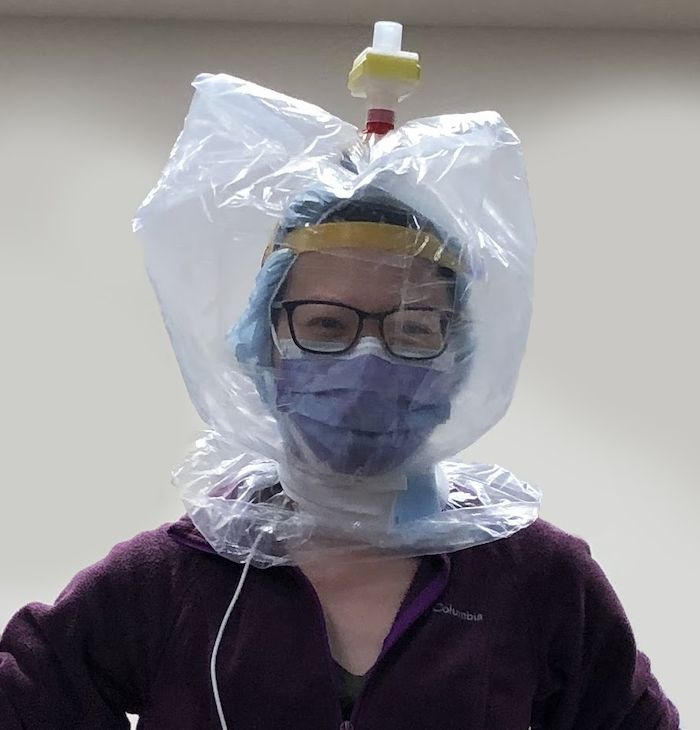

Health hackathon second-place winners demonstrate DIY affordable powered air-purifying respirator (PAPR) called the BunnyPAPR.

August 26, 2020

One of the key challenges at the start of the COVID-19 pandemic in the U.S. was a shortage of N95 and even less stringent facemasks. The Do-It-Yourself (DIY), Maker and 3DPrinting communities stepped up to this challenge with many innovative ideas for both face masks and shields.

While these efforts certainly helped lessen the facemask shortages, a deeper societal problem came into focus. How do people safely un-distance everyone so that things can get back to (a new) normal? According to the second-place winners of the recent Jersey City Rapid Maker Response Group (JCRMRG) health hackathon, the answer is an affordable and DIY powered air-purifying respirators (PAPRs) called BunnyPAPR.

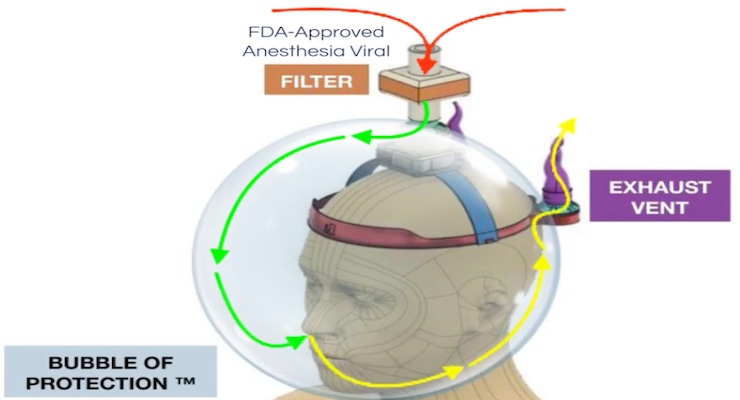

The CDC website explains that “a PAPR is an air-purifying respirator that uses a blower to force air through filter cartridges or canisters and into the breathing zone of the wearer. This process creates an airflow inside either a tight-fitting facepiece or loose-fitting hood or helmet, providing a higher assigned protection factor (APF) than the reusable elastomeric non-powered air-purifying half facepiece (half mask) or N95 N95 filtering facepiece respirators (FFRs).”

|

BunnyPAPR. (Image Source: Jersey City Rapid Maker Response Group (JCRMRG)) |

But PAPRs typically cost upward of $2,000. The BunnyPAPR hackathon team – including Howard Chong, Michael Noes, and Ethan White - thought a cheaper yet comparable solution was possible. Led by Dr. Kuo, an anesthesiologist in Seattle, WA, the core BunnyPAPR team created a $30 DIY substitute that they claim provides hospital-grade virus protection on the input and the output. Further, BunnyPAPR scales easily and quickly because it is made out of four commodity parts: A fan, a filter, a bag, and a battery- plus one custom plastic part.

The PAPR device takes the air that might be contaminated with the COVID-19 virus, actively filters the virus from the air, and delivers clean air to the user while also protecting the face. Dr. Kuo has tested the PAPR for oxygen, inspired CO2, and expired CO2 – all are at safe levels. He’s worn his BunnyPAPR for 11 straight hours, and every day at the hospital for two months.

The core hackathon team has identified huge product potential outside the hospital, internationally and in normal life, e.g., while attending sports events, amusement parks, or where users need to feel safer than using an N95 mask.

BunnyPAPR will use the freemium model: the free basic model targets non-commercial humanitarian work. The premium model offers upgrades, like quieter fans and prettier hoods, and will be sold directly to the consumer and licensed to large companies. Profits pay investors but also fund free distribution.

Due to proprietary issues associated with the sponsorships of the JCRMRG hackathon, the CAD files are not available for the BunnyPAPR. However, related PAPR hoses, connectors, and system CAD files can be found on open-source sites such as MakerBot Thingiverse.

Now that the hackathon is over, the JCRMRG plans to support the teams and the maker community by connecting both with additional resources and mentors. They also plan to develop new initiatives to use 3D printing and injection molding to make refinements to face shields and other needed personal protective equipment (PPE).

|

Air Purifying Respirators. Image Source: CDC PAPR |

John Blyler is a Design News senior editor, covering the electronics and advanced manufacturing spaces. With a BS in Engineering Physics and an MS in Electrical Engineering, he has years of hardware-software-network systems experience as an editor and engineer within the advanced manufacturing, IoT and semiconductor industries. John has co-authored books related to system engineering and electronics for IEEE, Wiley, and Elsevier.

About the Author(s)

You May Also Like