July 7, 2015

Engineers at Fuel Cell Energy have found a way to take advantage of a side reaction, unique to their carbonate fuel cell, as a potential, cost-effective solution to capturing carbon from fossil fuel power plants. The US Department of Energy appears to agree, having provided funding for early stage development.

This new application takes advantage of the fact that in a molten carbonate fuel cell (MCFC), carbon dioxide is produced at the fuel electrode and consumed at the air electrode. Furthermore, the CO2 is produced at an increased concentration. Typically, exhaust from a coal power plant contains about 10% CO2, while natural gas plants contain around 5%.

With the MCFC fuel cell emitting CO2 at a concentration of 70% that is then consumed, this effect can be exploited to extract concentrated CO2 from an exhaust stream using considerably less energy than the conventional approach that is being utilized in carbon capture projects such as FutureGen.

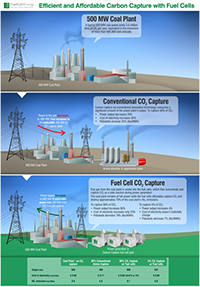

In conventional carbon capture and storage (CCS), exhaust gas is passed over an amine scrubber, which absorbs the CO2 gas. To release the gas, the scrubbers must either be heated or depressurized, both of which extract a significant energy penalty. After extraction, the CO2 must then be liquefied and pumped away to where it can either be sequestered underground or utilized. All of this could turn a 500 megawatt plant into a 400 MW plant by the time the carbon capture has been completed.

MCFC cells, unlike other fuel cells, use natural gas, rather than hydrogen, as their fuel. In practice, power plant exhaust gas would be fed directly into the air electrode and then extracted directly from the fuel electrode at the same time that natural gas is being fed in, without the need for heating or depressurization. This is where the energy advantage lies.

But it's really even better than that. The fuel cell, being an energy generation device, is also producing electricity at the same time it is extracting CO2. This way, said Tony Leo, Fuel Cell Energy's vice president of applications and advanced technology development, "you're able to meet a compliance obligation with an approach that provides an economic return."

MORE FROM DESIGN NEWS: Carbon Fibers Spearhead Automotive Lightweighting Effort

In this configuration, a 500 MW coal plant becomes a 900 MW hybrid coal/natural gas plant. This is the amount of added fuel cell capacity needed in order to effectively capture 90% of the CO2 emitted by the coal plant, which is the DOE's target. But because the rules for carbon capture are expected to be phased in, that means that fuels cells can be added incrementally, which effectively spreads out the capital requirements and makes it easier for utilities to comply.

The economics look something like this. Electricity from coal plants today costs approximately 6 cents per kilowatt-hour. Adding conventional CCS will nearly double that price to 11 cents per kWh. On the other hand, using MCFC technology to capture that CO2, while producing additional electricity, will only raise the price to an economically attractive 8 cents per kWh.

Finally, an additional feature of this chemistry is that roughly 70% of the NOx emissions are broken down as the gas passes through the fuel cell. This reduces the NOx scrubber requirements for the plant, and in the case of cleaner plants, such as those fired by natural gas, it could eliminate the need for NOx scrubbers entirely.

All of this can be done with proven technology that is already in the field. What remains is to integrate this fuel cell with the CO2 sequestration equipment at utility scale, which is the next step for Fuel Cell Energy.

RP Siegel, PE, has a master's degree in mechanical engineering and worked for 20 years in R&D at Xerox Corp. An inventor with 50 patents, and now a full-time writer, RP finds his primary interest in the cross-section of technology and society. His work has appeared in multiple consumer and industry outlets, and he also co-authored the eco-thriller Vapor Trails.

About the Author(s)

You May Also Like