Embedded Systems

The Embedded World Exhibition and Conference is taking place through April 11.

Embedded Systems

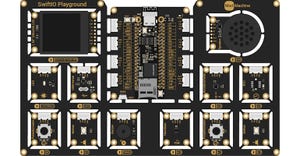

Embedded World Shows Future of Embedded SystemsEmbedded World Shows Future of Embedded Systems

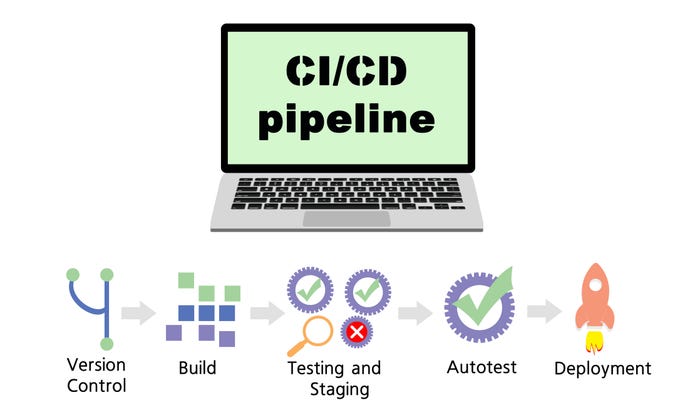

Boards, processors, software, and other technology present myriad choices for future robots, IoT, vehicle systems.

Sign up for the Design News Daily newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)