Before you can efficiently use industrial computers, you have to understand their configurations.

June 13, 2021

The global market for industrial computers is expected to grow from USD 4.4 billion in 2020 to USD 5.7 billion by 2025, according to a MarketsandMarkets report. The market growth is fueled by increasing demand for industrial IoT, a steady shift towards digitalized manufacturing, growing resource optimization in manufacturing, and stringent regulatory compliances.

Whereas commercial computers are typically used in an office environment, industrial computers are intended for manufacturing lines, process control, and data acquisition on the shop floor. For example, an application may simply require the input/output (I/O), such as the serial port offered by the motherboard. In other cases, expansion cards are installed to provide analog and digital I/Os, specific machine interfaces, expanded communications ports, and so forth, as required by the application.

Industrial computers range from rack-mounted industrial embedded computers with multiple I/Os to industrial tablet panel PCs.

Building With an Industrial Computer

To build with an industrial computer, you first have to understand what they can do. Developing or implementing the optimal industrial PC depends upon the application needs but falls into three categories: 1) design your own, 2) off the shelf, and 3) industry-specific. Most prominent providers of industrial computers – like Kontron, Comtronix, WinSystems, and the like – offer platforms for all three categories.

For special-purpose industrial computers, it may be necessary to use a vendor's design manufacturing service. The customer specifies all aspects of the computer, from its size, I/O port configuration, power, computer performance, connectivity, and more.

Perhaps the easiest way to build an industrial computer is to buy a branded ready solution or commercial-off-the-shelf system. These are generalized computers not dedicated to specific industry needs.

The third category of industrial computers is a compromise between specialized and off-the-shelf computers, namely, one’s pre-build for specific industries. Such industrial computers typically fall into these subcategories:

Manufacturing – Used to assess critical data about a production-line bottleneck or panel PCs controlling a CNC machine task, these systems are often ventless and fanless and support current wireless radios, e.g., WiFi, Bluetooth, and 4G LTE)

Warehouse and Distribution – Used to track inventory from slot locations to the dock door. Wireless Wi-Fi modules must stay connected while roaming in high-density racking infrastructures.

Transportation and Logistics - New regulations require accurate reporting, vigilant record-keeping, continuous visibility, and rapid information processing. These rugged tablet computers and industrial computers must be easily embedded or mounted in vehicles and on forklifts.

Building Automation – These computers are often enclosed in rackmount servers. They must keep a building’s vital components secure while delivering an effective means of reducing energy and operation costs. Building automation computers are needed for HVAC, access control, and security and surveillance systems.

Decision Criteria

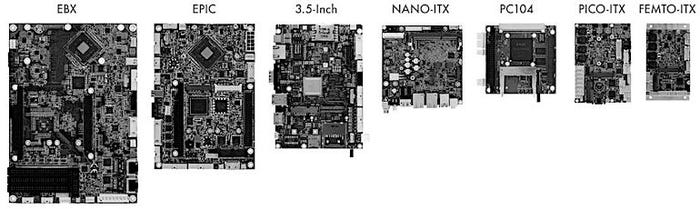

There can be many decision points when building and implementing industrial computers, such as the size or form factor of the PC board. Most PCs used in industrial applications are referred to as a computer-on-module (COM), a single-board computer (SBC) – often used in commercial embedded computer systems. The COM is analogous to a system on chip (SoC) and system in package (SiP), in that a COM contains full computer capabilities on a single board.

Unlike desktop PC, single board computers do not rely on expansion slots for peripheral functions or expansion. Instead, an SBC often occupies one slot in a rack-mounted cabinet – typically a backplane position. The remaining slots are filled with a variety of I/O modules as needed by the particular industrial application.

Which form factor single board computer (SBC) should a designer cho0se? The answer depends on the particular industrial application, performance requirements, I/O needs, and other constraints. Even if the correct form factor can’t be found, a customized version can be built. (Image Source: WinSystems Press Release)

Small board computers often rely on standardized computer form factors intended for use with a backplane enclosure. When a backplane is used with a plug-in single board computer (SBC), the combination provides the same functionality as a motherboard, providing processing power, memory, I/O, and slots for plug-in cards. Backplane enclosures include the following: CompactPCI, PXI, VMEbus, VXI, and PICMG.

The result is similar to having a system built with a motherboard, except that the backplane determines the slot configuration. Backplanes are available with a mix of slots (ISA, PCI, PCI-X, PCI-Express, etc.) and fit in a 19" rackmount enclosure.

John Blyler is a Design News senior editor, covering the electronics and advanced manufacturing spaces. With a BS in Engineering Physics and an MS in Electrical Engineering, he has years of hardware-software-network systems experience as an editor and engineer within the advanced manufacturing, IoT and semiconductor industries. John has co-authored books related to system engineering and electronics for IEEE, Wiley, and Elsevier.

About the Author(s)

You May Also Like