New chip is targeted at defense and commercial aircraft, as well air traffic control, surveillance, and even 5G communications.

May 18, 2018

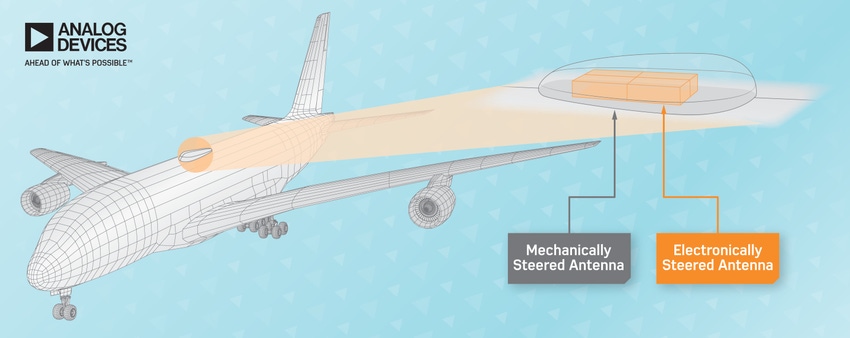

A new beamforming chip promises to shrink the size and weight of aircraft antennas by eliminating the need for mechanical steering linkages.

The chip could serve in radar for defense aircraft and for in-flight broadband on commercial jets. Analog Devices, Inc., maker of the new chip, also foresees it being used in air traffic control, surveillance, weather monitoring, and even 5G communications.

ADI engineers say the key is the product’s inherent ability to cut size and weight. “By going to an electronically steered antenna design, we are able to reduce the size of the antenna element itself and eliminate the mechanical arm and motor required to turn the dish,” Mike Chowkwanyun, product line manager for phased-array ICs, told Design News. “So you could have a much smaller flat antenna design that sits almost flush against the plane’s fuselage, and requires a smaller dome to cover the antenna.”

|

The ADAR1000 chip replaces 12 discrete components needed for antenna phase-gain adjustments and digital controls. (Image source: Analog Devices, Inc.) |

Known as the ADAR1000, the chip replaces 12 discrete components needed for antenna phase-gain adjustments and digital controls. It’s designed for frequency ranges between 8 GHz and 16 GHz.

ADI engineers say the new technology could shrink the weight and volume of a typical aircraft radar antenna by as much as 50%. Such antennas typically reside in the nose cones of fighter jets and are accompanied by mechanical arms that steer the antenna. Similarly, commercial planes use a conformal antenna and a steering linkage covered by a dome.

|

Used for in-flight broadband applications, the new technology could shrink the weight and volume of a typical aircraft radar antenna by as much as 50%. (Image source: Analog Devices, Inc.) |

“By going to an electronically steered antenna, we can lower the profile of the antenna dish itself—lower the weight and lower the volume,” Chowkwanyn told us. “And since there are no mechanical moving parts at all, it helps improve long-term reliability.”

The ADAR1000 also offers a plug-and-play design that ADI says will appeal to designers with little or no radio frequency (RF) experience. “We are able to allow smaller customers who may be new to phased array, or who may lack RF experience, to put together a radio that utilizes the benefits of phased array for whatever applications they’re designing for,” Chowkwanyun said.

Somewhat surprisingly, ADI is also targeting the new technology at applications outside of defense and avionics. Even there, size and weight reduction are important, Chowkwanyun said. “The phased array is now being evaluated outside of the traditional group of users,” he told us. “We’re starting to see phased array being considered for satellite and 5G communications.”

Read More Articles on Electronics and Test Technology

New Material Paves Way for Smaller, Higher-Density Electronics

The Soon-to-be-Extinct Embedded Software Engineer

Teledyne LeCroy Breaks Out High-Res, High-Bandwidth Scope

Senior technical editor Chuck Murray has been writing about technology for 34 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and auto.

2017 Call for Speakers INSPIRE. COLLABORATE. INNOVATE. Atlantic Design & Manufacturing, part of the largest advanced design and manufacturing industry event on the East Coast, is the annual must-attend trade show for discovering the latest in design engineering. Source from the region's most comprehensive collection of cutting-edge suppliers, deepen your expertise with free, conference-level education, and network with thousands of professionals who can help you advance your projects — and your career. From prototyping to full-scale production, one lap of the show floor will help you overcome your toughest manufacturing challenges and keep you up to speed on innovations transforming the industry. Everything you need to take projects to market faster and more cost effectively is here. Click here to register for your free pass today! |

About the Author(s)

You May Also Like