Tesla CEO Elon Musk is learning what Fiat's Sergio Marchionne already knew: Squeezing profit from an entry-level electric vehicle is a monumental task that requires a great deal of patience.

May 26, 2018

|

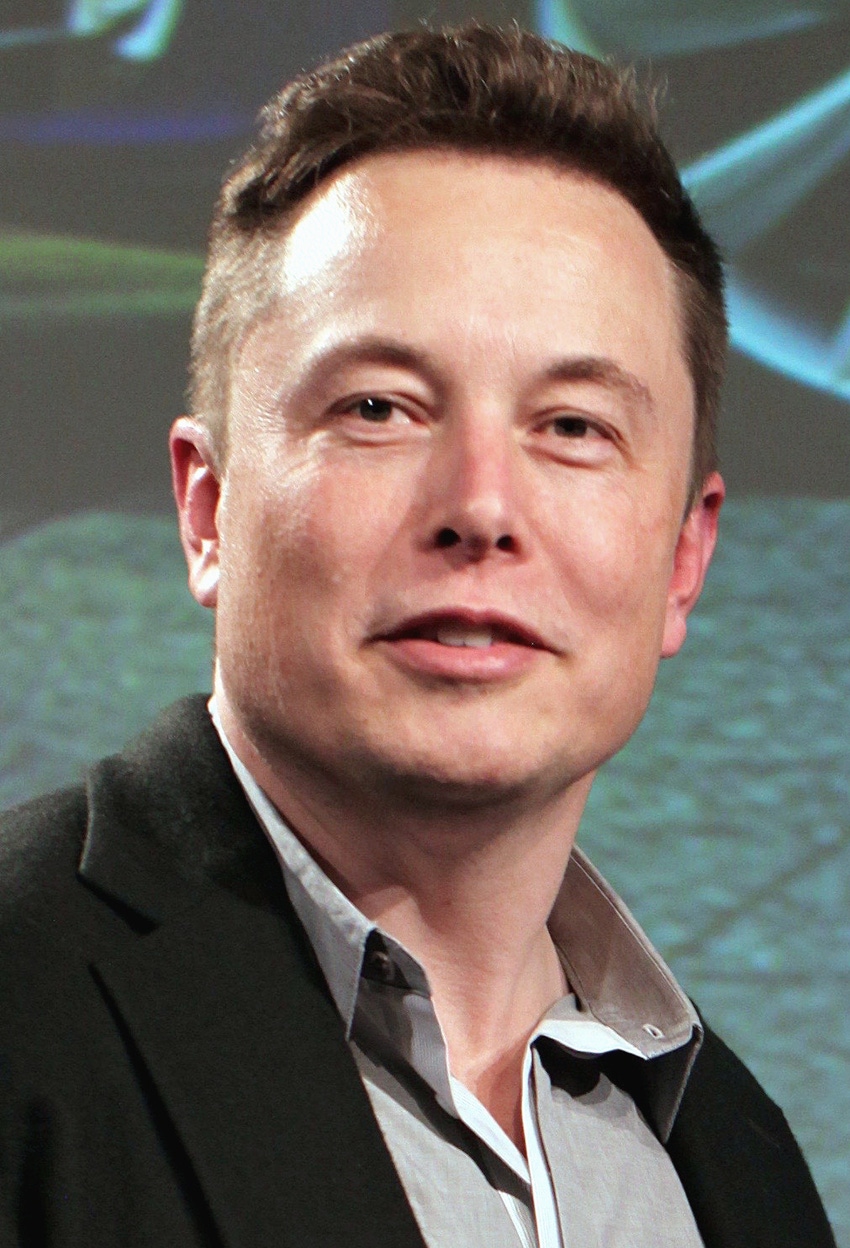

Last week, Elon Musk (right) tweeted that shipping $35,000 versions of the Model 3 right now would cause Tesla to “lose money & die.” (Image source: Wikipedia/ By Steve Jurvetson). |

Many lessons can be learned from Elon Musk’s recent tweets about the trials and tribulations of the Model 3 electric car, but the main one is this: Musk and Sergio Marchionne have a lot in common.

Musk’s most revealing tweet occurred last week, when he said that shipping $35,000 versions of the “affordable��” Model 3 right now would cause Tesla to “lose money & die.” He added that he needs three to six months after reaching production levels of 3,000 to 5,000 cars a week, just for Tesla to stay alive.

As if those words weren’t shocking enough, Musk also announced that Tesla has hatched a plan to market a souped-up, $78,000 version of the Model 3. The underlying plan is for Tesla to sell higher-priced versions of the Model 3 until it can make ends meet with the $35,000 models. This would be accomplished by boosting performance and adding such features as bigger battery packs, automated driving capabilities, glitzy wheels, and colors other than black. Only after that could the company begin delivering lower-cost versions to the 400,000-plus customers who have plunked down $1,000 deposits over the past few years.

Not surprisingly, Musk’s tweets weren’t met with a lot of happiness—even among the media that has helped hype the company for the past decade. In a typical headline, the Los Angeles Times called the Model 3 unaffordable for the masses. Similarly, US News & World Report ran a story saying that Tesla lost $14,000 on each of the Model 3s it delivered (based on an average sales price of $54,000) in the first quarter of 2018.

The Old Reality

In essence, Musk’s comments aren’t much different from those of Sergio Marchionne, the plain-spoken chairman and CEO of Fiat Chrysler Automobiles (FCA). In 2014, Marchionne made this blunt statement about the little Fiat 500e electric car: "I hope you don't buy it because every time I sell one, it costs me $14,000."

Marchionne was, of course, heavily criticized for his comment. But the criticism seldom mentioned the fact that Marchionne recognized the inevitability of electrification. He frequently said that as emission standards were tightened, the auto industry would naturally gravitate toward a combination of combustion and electrics. Under his leadership, Chrysler even launched its effort to build the Pacifica plug-in hybrid minivan.The lesson here is that Marchionne’s reality was not much different than the reality now facing Elon Musk. And that same reality is shared by the rest of the auto industry, which has long known that the entry-level market would be a tough nut to crack for the electric car. In fact, the auto industry has known for decades that all small cars—even those with internal combustion engines—exist on razor-thin profit margins.

RELATED ARTICLES:

Somehow, though, that reality has managed to elude much of the public, the media, and even Wall Street. That’s why Tesla’s market cap is so absurdly high. Today, Tesla’s market value is about $450,000 per car sold—about 16 times that of BMW and 90 times that of GM.

What this means is that investors have showered money on Tesla, largely because of its vision of the future. And—let’s be honest here—that assumption is based on the fact that Tesla is a Silicon Valley company led by a genius, whereas the conventional auto industry is characterized as a Midwest, Rust Belt industry with one foot firmly planted in the past.

The corollary to this assumption is that Silicon Valley knows how to quickly drive the cost out of new technology and will do so in batteries and electric cars. In 2010, The New York Times even explained this in an article that introduced the concept of “Moore’s Law for Electric Cars.”

Which, of course, is ridiculous. Gordon Moore’s famous “law” applies to semiconductor chips, not to batteries and not to cars. The cost of electrics is never, ever going to drop the way semiconductor chips did for 40 years.

Detroit knows this and so does Musk. But the public doesn’t, which is why the concept seems to linger.

The irony now is that the viewpoints of the two sides are converging. Detroit (which has brilliant engineers, too) now knows what Musk has taught—that there’s a market for electric cars in the luxury sector. And Musk is learning what Detroit already understood—that squeezing profit from an entry-level electric vehicle is a monumental task that requires a great deal of patience.

Maybe Sergio Marchionne actually knew what he was talking about.

Senior technical editor Chuck Murray has been writing about technology for 34 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and auto.

2017 Call for Speakers INSPIRE. COLLABORATE. INNOVATE. Atlantic Design & Manufacturing, part of the largest advanced design and manufacturing industry event on the East Coast, is the annual must-attend trade show for discovering the latest in design engineering. Source from the region's most comprehensive collection of cutting-edge suppliers, deepen your expertise with free, conference-level education, and network with thousands of professionals who can help you advance your projects — and your career. From prototyping to full-scale production, one lap of the show floor will help you overcome your toughest manufacturing challenges and keep you up to speed on innovations transforming the industry. Everything you need to take projects to market faster and more cost effectively is here. Click here to register for your free pass today! |

About the Author(s)

You May Also Like