Mentor Graphics CEO Wally Rhines contends that it’s not practical for automakers to drive the billions of miles needed to test self-driving vehicles.

April 2, 2018

The task of validation and verification of autonomous cars is expected to be unlike anything in the 130-year history of the automobile. Experts estimate it could require as many as nine billion miles of test driving to “teach” the vehicles how to react to all imaginable on-road scenarios. Increasingly, however, automotive engineers and suppliers say that it’s not realistic to log billions of miles of road testing. They argue that much of the process will need to done in model-based simulations. To learn more about the dilemma facing the auto industry, Design News talked with Wally Rhines, president and CEO Mentor, a Siemens Business. Rhines became CEO of Mentor Graphics in 1993. He holds a BS in engineering from the University of Michigan, an MS and a PhD in materials science from Stanford University, and is a Lifetime Fellow of IEEE.

DN: Toyota’s CEO said in 2016 that it will need to do nine billion miles of test driving before it puts autonomous vehicle technologies in its cars. Why does verification and validation require so many miles?

RHINES: That number represents the phenomenal amount of variations of inputs you have to test in a driverless car, as compared to today’s cars. In today’s conventional cars, you could do final testing, driving fleets of cars in South America or Alaska for hundreds of thousands of miles, maybe even millions of miles. But not billions. The reason, of course is that you’re testing for things with an autonomous car that you don’t have to test for in today’s cars. You’ve exploded the number of test cases.

|

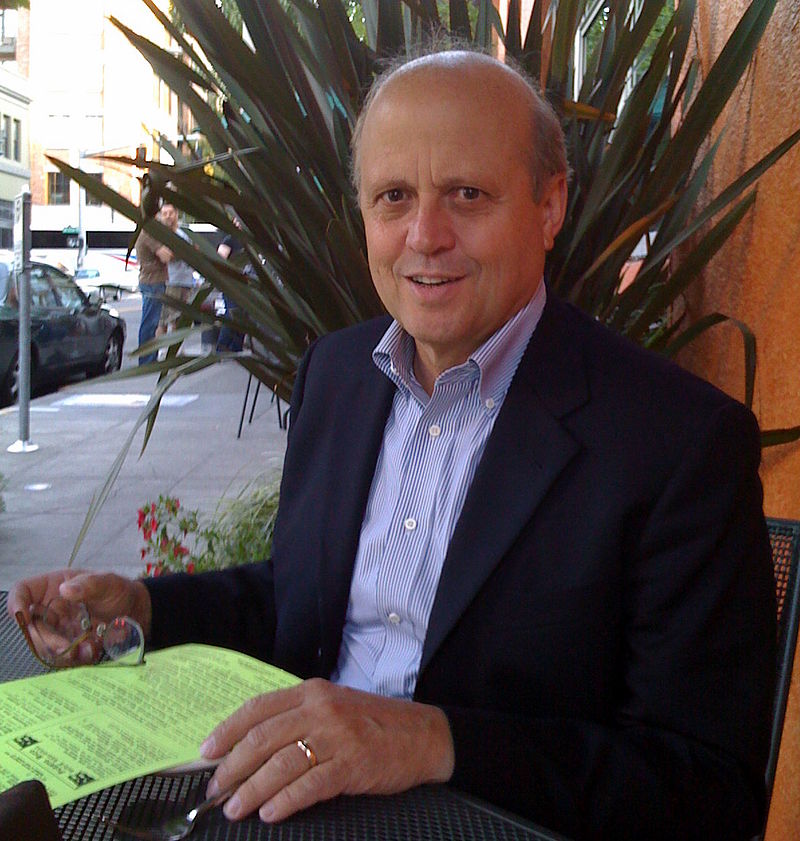

Mentor CEO Wally Rhines: “Automakers will delay a product introduction by a few weeks, but not 50 years.” (Source: Wikipedia/By Paula Rhines) |

DN: Why can’t it be done physically? Is it mostly development cost or a time issue?

RHINES: First of all, you can’t do the breadth of testing in a reasonable amount of time. Take that nine-billion-mile figure: That’s the equivalent of getting a fleet of 300 cars, driving them 60 miles per hour, 24 hours a day for 50 years to get all your test data. Automakers will delay a product introduction by a few weeks, but not 50 years.

Second, there’s the issue of practicality. There are so many things you can’t test physically. You can’t run into a human being; you can’t kill an animal; you can’t drive off the road. All these things can be tested virtually, with no real consequences. You’re just paying for it with computer cycles. So, from a practical point of view, virtual verification is inevitable.

DN: Can we really feel confident that by doing model-based approaches we can simulate 100% of the things that unpredictable humans would actually do?

RHINES: 100% is a big number, so we will have to evolve. As the world gains more autonomous driving experience, there will be new occasions that were not anticipated. But those occasions will be miniscule compared to amount of verification that we will be able to do, and the variety of things we will be able to anticipate.

DN: Will automakers develop their own simulation tools in house, or will they go to vendors for this?

RHINES: We are told that Google has developed some of its own tools, but as far as we know, they aren’t providing them to their competitors. Some people will develop their own, but as with all design automation, there will eventually be standard tools that people expect to use that have far greater capability than anything they could develop themselves.

It’s going to be a good business. There are over 100 announced developers of autonomous vehicles. And there over 300 developers of electric cars. These are people who have bought only minimal design automation software in the past.

I don’t kid myself that there will be 300 manufacturers of electric cars ten years from now. But on the way there, there will be more than 300 who buy design automation software in order to compete, to see who the winners are.

DN: Even if you solve the validation and verification problem, aren’t there other issues of practicality on the way to creating a Level 5 autonomous car?

RHINES: There are certainly other issues of practicality. If you don’t get the compute processing power down by an order of magnitude – say, by a factor of 20 – then you will cut the driving radius of an electric car in the city by about 30% and on the highway by about 10%. That’s how much power the processing consumes.

Then we will have the infrastructure issues. We don’t have the charging stations nationwide, even though we are ahead of other countries. And yet some countries have said they will outlaw gasoline and diesel fuel between 2025 and 2040. The question is, do they have enough charging stations so that everyone won’t have to stand in line to recharge their cars? There definitely are still issues that need to be worked out.

If you have a comment, send it directly to [email protected] and we will publish it in a future article. Just keep it concise (100 words or less) and type the words “story comment” in the subject line.

Read More Articles on Automotive Technology

Siemens to Roll Out New Simulation Platform for Self-Driving Cars

Suppliers Prepare New Products, Processes to Meet 54.5-MPG Standard

NXP Rolls New Development Platform for EVs, Hybrids

GM, Waymo Top Ranking of Autonomous Car Leaders

Senior technical editor Chuck Murray has been writing about technology for 34 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and auto.

Use the Code DESIGNNEWS to save 20% when you register today! |

About the Author(s)

You May Also Like