Electronics industry veteran offered insights to design engineers on the importance of understanding the manufacturing process.

July 23, 2020

Pasquale (Pat) Octavious Pistilli passed away on Wednesday, July 15th, 2020. He was 89 years old.

Ten years ago, I had the opportunity to interview Pistilli shortly after he won the ESD Alliance’s prestigious Phil Kaufman Award. He was being honored for his efforts in formalizing the electronic design automation (EDA) industry and as founder of the Design Automation Conference (DAC), now in its 57th year. DAC is a major conference in the industry that develops the software programs needed to design and test semiconductor chips.

Pistilli and his wife Maria were also known for starting a successful conference management company known as MP Associates, that has provided services for DAC, IEEE IMS and many other technical shows over the years.

What follows is my conversation from October of 2010, in which we talked about the critical skill sets needed for today’s young engineers.

Blyler: Your career started in engineering but grew beyond a traditional role. What advice would you offer to young engineers entering today’s workforce?

Pistilli: When I speak at engineering schools, as I recently did at Colorado University, I stress that in industry you design something once but build it thousands of times. So whatever you design, you must design it for manufacturing. Many undergraduates think that engineering stops with design, that a project is finished once it is designed. That perspective is understandable but leads to big failures because manufacturing is often unable to use a design. Why? The design may be incomplete or perhaps not understandable to the manufacturing folks.

I recommend that, whatever you design, you must consider how the design will be manufactured and by whom. You need to know the capabilities of the manufacturers as well as their manufacturing procedures.

I worked at Bell Labs in the 60’s and 70’s. Back then, I would send every newly hired programmer in my group to work for three weeks in the manufacturing shop. In this way, the programmers would understand where their designs ended up and why the designs must be presented in a way that the manufacturing people would readily understand.

|

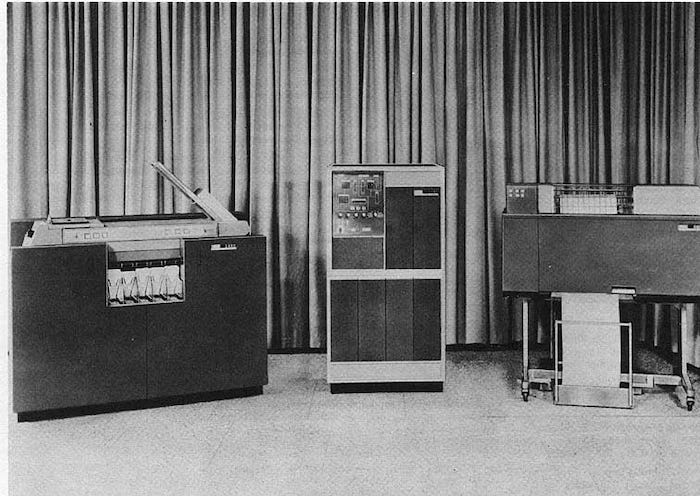

IBM 1401 Data Processing System used for early EDA design. (Image Source: By Gobierno de los Estados Unidos Public Domain) |

Blyler: What career-related advice do you offer?

Pistilli: I tell young engineers not to get set into a mindset of only wanting to work on one thing or another, like wanting to work only on integrated circuits (IC) design. Instead, try to start your career by looking over the big picture. After all, ICs haven’t replaced the printed circuit board. We are still doing PCBs. Plus you have to put an IC onto something to get it into the complete system. Young engineers should be aware of and concentrate on all aspects of the system.

Blyler: Indeed, all of the major IC tool manufacturers are moving toward a more complete product space that includes ICs, packages, boards and even software/firmware. How does this affect the way in which young engineers select their first job?

Pistilli: Well, in these economic times, when you get a job offer you just thank God and take it. But once you get to work you should look within the company to get a sense of the bigger picture.

If you don’t get a job right away, you might decide to work toward a graduate degree. But be careful. Many companies are not looking for PhDs as much as they did in the past. One of the reasons is that companies are no longer doing heavy research. Instead, companies are investing more in design. Research into new design tools is still being done, but more seems to be happening at universities through funding sponsored by the big EDA companies.

Blyler: How can recent engineering graduates get help in developing their careers while helping their employers develop good systems or products?

Pistilli: The most important thing for a young engineer is to network. This is one of the biggest benefits of attending technology conferences like DAC, i.e., the opportunity to network with other engineers. Networking occurs after paper sessions, during lunch breaks, at dinner – all the time during a trade show.

Blyler: Thank you and congratulations on receiving this year’s (2010) Phil Kaufman Award!

John Blyler is a Design News senior editor, covering the electronics and advanced manufacturing spaces. With a BS in Engineering Physics and an MS in Electrical Engineering, he has years of hardware-software-network systems experience as an editor and engineer within the advanced manufacturing, IoT and semiconductor industries. John has co-authored books related to system engineering and electronics for IEEE, Wiley, and Elsevier.

About the Author(s)

You May Also Like