April 3, 2013

Thomas Edison was at the forefront in the early days of the electrical industry. He was an empiric who spared no expense in his pursuit to push forward. Edison famously said, "I have not failed. I've just found 10,000 ways that won't work."

Then, along came a US Navy ensign, inventor of the inverted dynamo, Frank Julian Sprague. Opposed to the trial-and-error design methods, Sprague taught the Edison Laboratory mathematical methods, aka the scientific method. Deriving optimum parameters mathematically saved quite a bit of costly experimentation. Sprague went on to use mathematical methods to correct many of Edison's electrical systems, improving performance and cutting cost -- the earliest example that virtual design is essential.

Imagine saying the same thing in the workplace today: "I have tried 9,751 different designs that didn't work, on to the next." Edison controlled the world's electrical needs, and had all of the money to show for it. Anything was possible then. Today, budgets are not the same. Companies scrap over small slices of a percent, even in a niche market. Every penny must be saved.

With all the computing power at the world's fingertips, virtual design has gone from pen and paper to a complete design environment populated with virtual components that can be constructed and tested in larger, more complex, systems. With virtually no overhead in building multiple revisions, it only makes sense to design virtually first, before a build is attempted. The virtual approach should also be applied to testing, monitoring, and evaluating. Often enough, design on the job follows the Edison style, but it's time to go Sprague -- it's time to go virtual.

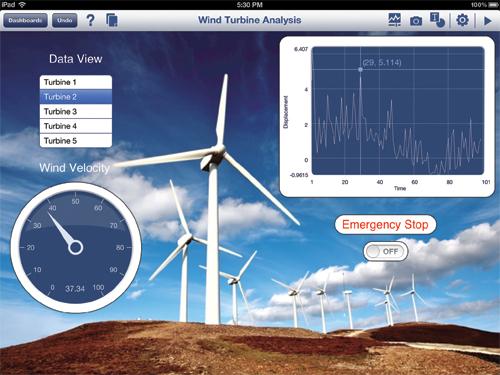

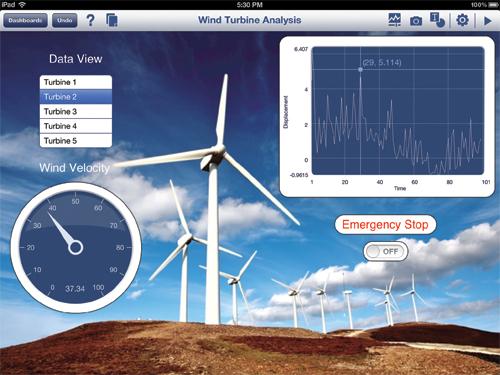

Before our world was inundated with rich information and vibrant visualization, embedded design applications were hampered by rudimentary user interfaces. This situation severely limited the amount of information that could be conveyed to operators and technicians. In fact, not long ago, user interfaces were purely mechanical, before automation and computer-based human machine interfaces (HMIs) existed.

HMIs go virtual

Virtual Instrumentation propelled computer-based HMIs into the commonplace. This allowed embedded designers to have more flexibility in the types of data displayed. These advances in monitoring software also set new expectations for intuitive interfaces and interface designs.

Previously, user interfaces were very difficult to create. Embedded designers drew each indicator and control -- drag-and-drop UIs did not exist. Not only did embedded designers draw each pixel, but the controls didn't include functionality -- engineers had to hand code the capabilities of each control. For example, a control did not have built-in knowledge of data types, so users had to decide at design time, rather than at run time, which data format they wanted, and they had to work through any format incompatibilities ahead of time.

Fortunately, the trend toward more capable, functional, and easier to design HMIs continued.

About the Author(s)

You May Also Like