November 4, 2016

The huge 3D printers that make very large, high-value metal prototypes and production parts for aerospace and defense OEMs are now speeding up automotive tooling. Sciaky's electron-beam additive manufacturing (EBAM) systems are helping an automotive manufacturer to cut costs and time needed for making and repairing tooling and stamping dies.

EBAM systems can produce parts ranging from 8 inch (203 mm) to 19 ft (5.79m) long in only a few days, as well as smaller and larger parts depending on the application. Until a couple years ago, Sciaky kept the EBAM process in-house and operated its machines as a service to the military and Tier 1 contractors, including DARPA, the US Air Force, Lockheed, and Boeing, among others. In 2014 it also began selling its huge metals 3D printers commercially, in addition to its EBAM services.

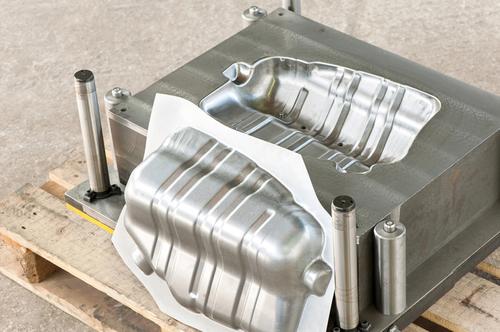

Sciaky's electron-beam additive manufacturing (EBAM) systems are helping an automotive manufacturer to cut the costs and time needed for making and repairing tooling and stamping dies. This forming die, although not made by the automotive manufacturer, is an example of what can be created using Sciaky's EBAM technology.

(Source: Sciaky)

The automotive manufacturer used an EBAM system for customized repairs and cladding operations on several high-volume parts, as well as to deposit complicated tooling features. The 3D-printed tool was put into production after a successful proof of concept. The tool was created on Sciaky's EBAM 300 Metal 3D Printing System that resides at Sciaky's facility in Chicago, Ill., a company spokesman told Design News.

EBAM technology has been used much more widely than high-value titanium parts and aerospace applications. "We have provided 3D-printed solutions to customers in a variety of industries like automotive, agricultural, defense, nuclear, oil & gas, and sea exploration using a wide variety of metals like stainless steel, tantalum, tungsten, Inconel, and niobium," said Bob Phillips, vice president of Sciaky's parent company, Phillips Service Industries.

Designers & Innovators. Learn more about some of the latest designers and innovators and what they're up to at ESC Silicon Valley, Dec. 6-8, 2016 in San Jose, Calif. Register here for the event, hosted by Design News’ parent company, UBM.

Designers & Innovators. Learn more about some of the latest designers and innovators and what they're up to at ESC Silicon Valley, Dec. 6-8, 2016 in San Jose, Calif. Register here for the event, hosted by Design News’ parent company, UBM.

This process can make high-quality, large-scale parts as large as 19 ft x 4 ft x 4 ft or longer, such as an entire wing box for a jet fighter plane. It's used for making parts from high-value metals such as titanium, Inconel, tantalum, tungsten, and stainless steel. The process can be used in prototyping, manufacturing, or even repairing and remanufacturing. To ensure consistency and repeatability, an adaptive, closed-loop control system automatically maintains key process variables throughout a part's build process.

In Sciaky's EBAM system, a fully articulated, movable electron beam wirefeed welding gun deposits metal layers on a substrate plate. Deposition rates are 7 to 20 lb per hour depending on the material, the fastest metal deposition process available. Many EBAM systems have dual wirefeed configurations to increase deposition efficiency and simplify switching materials. The process makes near-net shapes, which require only a small amount of post-production machining, and also reduces waste.

READ MORE ARTICLES ON 3D PRINTING:

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 29 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

About the Author(s)

You May Also Like