April 18, 2013

Additive manufacturing (AM), including 3D printing, has the potential to upend manufacturing supply chains, according to the new report from Lux Research, "Building the Future: Assessing 3D Printing's Opportunities and Challenges." The catch is, it will take a while, and the results will depend on how quickly costs come down, and throughput goes up.

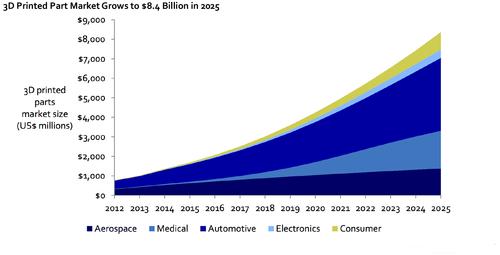

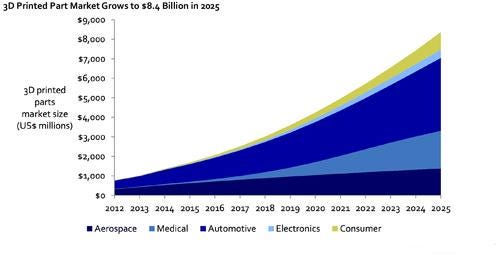

Although consumer applications -- such as custom jewelry, toys, and art -- have gotten a lot of attention, consumer products will remain a small portion of the 3D-printed parts market, Anthony Vicari, Lux Research associate and the lead author of the report, told Design News. These will grow $17 million from 2012's $777 million total to $894 million in 2025, when the total market value reaches $8.4 billion. Between now and then, the overall market will grow at an aggressive 18 percent per year.

Both prototypes and production parts for automotive, medical, and aerospace segments will represent 84 percent of the entire market by 2025. Today, prototypes represent about 90 percent of uses, and most of the major aerospace and automotive OEMs have some kind of 3D printing division to make prototypes in-house, said Vicari. By 2025, though, this proportion will drop to 47 percent.

The big growth will be in small-volume manufacturing, led by automobile parts and aerospace engines; this will jump from $1 million in 2012 to $1.1 billion in 2025. The production parts that will be most amenable to adoption of 3D printing will be those that need a lot of customization, don't require high volumes, and are somewhat less cost sensitive.

The report looked at nine different 3D printing technologies: stereolithography (SLA), selective laser sintering (SLS), selective heat sintering, powder bed inkjet printing, fused filament fabrication, polyjet, digital light processing, laminated object manufacturing, and electron beam melting. It did not include related technologies such as CNC milling or metal injection molding (MIM).

Although the $11 million medical 3D printing sector is small, it's growing fast, and will become $1.9 billion by 2025. Prices will drop for printers such as Stratasys's Objet30 OrthoDesk for dental devices, as well as for materials and scanning technologies.

Before the shift can happen to a majority of production parts in aerospace, automotive, and medical, the report concludes that several other changes must occur, primarily a rise in throughput and a drop in costs. "Currently, throughput is good for 1 to 10 pieces, but once you need to make more than few hundred or even thousand pieces of a part, 3D printing is not likely to be the most affordable way to manufacture something," Vicari told us.

Methods for increasing throughput vary by specific 3D printing technology. For example, just increasing the build chamber and the number of nozzles only gets you so far, since the process is still limited by the time it takes to deposit the material. There's been relatively limited development in machine throughput in recent years, perhaps because of the tradeoffs between throughput and minimum resolution. That's why the report concludes 3D printing is not likely to penetrate the high-volume manufacturing segment.

About the Author(s)

You May Also Like