February 3, 2012

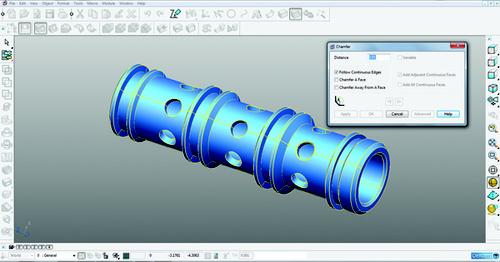

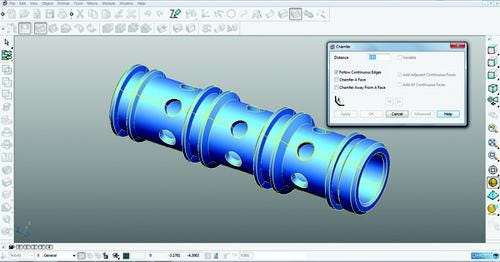

PartMaker Inc., a division of Delcam Plc best known for its specialty CAM software designed for automating the programming of multitasking Turn-Mill Centers and Swiss-type lathes, has come out with a modeling module intended to bring 3D CAD capabilities to CNC machinists.

The software can drive the full spectrum of CNC (Computer Numerical Control) applications, including milling, turning, wire EDM, multitasking, Turn-Mill, and Swiss-turning. PartMaker has always offered a base level of CAD, but it had limited functionality and only provided 2D, not 3D capabilities, according to Hanan Fishman, PartMaker's president. "PartMaker has always had basic CAD -- I liken it to AutoCAD for the machinist. In other words, it has 2D drawing capabilities and is designed for minimum keystrokes and to be easy to use by shop floor personnel," Fishman told us.

Though 2D functionality has long been sufficient, requirements are starting to change for the PartMaker customer base -- the bulk of which consists of medical device manufacturers. Most of them now work regularly with 3D models, and it isn't uncommon for the CNC software to run into data quality issues when working with IGES and STEP files, which is typically how partners working in different CAD systems exchange models, Fishman said.

Unlike native 3D CAD files, IGES and STEP files do not maintain a rich set of data about the product in a history tree. Companies with concerns about sharing intellectual property convert their native CAD files into so-called dumb STEP or IGES files. This strips out much of the intelligence and leaves only a surface model. This is perfect for sharing, but not oversharing.

Manufacturing teams typically have to recreate that intelligence before they can send the file off to a machinist to create a part with the proper tolerances. However, the recreation process is fraught with translation issues, and Fishman said PartMaker Modeling's vision of CAD is designed to address that specific problem.

As a hybrid modeler supporting surfaces and the Parasolid industry-standard solid modeling kernel, PartMaker Modeling includes an internal Solid Doctor tool that automatically repairs models. It turns the simplified IGES or STEP surface model into a solid model that can drive CNC machines and 3D simulations without any translation issues. It also frees machine shops from having to invest in multiple CAD systems, most of which have capabilities they don't use or need, Fishman said.

"This allows people to accept poor-quality data from all sorts of different systems and repair it and turn it into a watertight, machineable solid model," he said.

Further reading:

About the Author(s)

You May Also Like