Maplesoft has become a SolidWorks Certified Solutions Partner, thus integrating the two companies' software.

May 9, 2016

Maplesoft has become a Dassault SystèmesSolidWorks Certified Solutions Partner. The partnership will allow Maplesoft’s tools to easily integrate with SolidWorks, making it easier for engineers to see how mechanical CAD models behave as part of a larger multi-domain system.

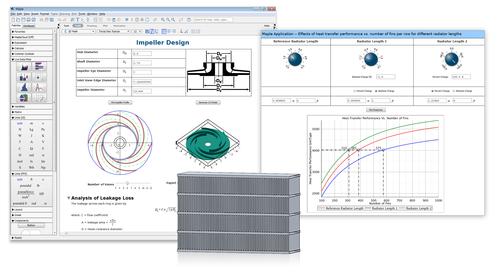

The integration of Maple with SolidWorks allows users to enhance their analysis with auditable design documents that contain math, text, visualization, and plots, while revealing the engineering knowledge and assumptions that are otherwise hidden in spreadsheet analyses.

(Source: Maplesoft)

The integration between Maplesoft and SolidWorks is part of an industry-wide movement to make design software tools interoperable –- thus making the tools user friendlier. The integration of SolidWorks with Maplesoft was created to give users a seamless way to import CAD model parameters into the company’s Maple program. The goal is to give users access to Maple’s advanced mathematical analysis tools. Users can then export updated model parameters from Maple to SolidWorks.

With this integration, Maple users will be able to open a part or an assembly from SolidWorks while in the Maple document. “You can ask about the dimensions of a CAD design. The data becomes available in the Maple document,” Laurent Bernardin, EVP and chief scientist at Maplesoft, told Design News. “You can set up a test or optimize an aspect of your design –- say a new length or new thickness -– and take the new value and put it back into the SolidWorks drawing. It’s a bi-direction way of using live calculations.”

Are you eager to learn more about CAD/CAM tech? Here is your opportunity! Join your peers at Atlantic Design & Manufacturing June 14-16, in New York!

The integration also includes Maplesoft’s modeling and simulation platform, MapleSim. By importing multi-body CAD models from SolidWorks into MapleSim, users can automatically capture the kinematic and kinetic properties of the model components. They can also evaluate how mechanical CAD models will behave as part of a larger, multi-domain system, and apply MapleSim's advanced analysis tools to improve and optimize designs.

As with the Maple integration, users can call on MapleSim while working within SolidWorks, or vice versa. And it can be done without jumping from one program to another. “You can run a simulation and get a dynamic on how the design will perform. You can visualize the simulation using graphics. If it’s a mechanical simulation, you can view it as 3D animation,” said Bernardin. “You can integrate domains such as mechanical or electrical in one system model and see how the different pieces of the design will interact and affect each other. You can also apply constraints such as regulation or efficiency.”

READ MORE ARTICLES ON DESIGN SOFTWARE:

This allows design engineers to run analysis on a product within SolidWorks, adding and analyzing components without importing and exporting to different programs. “SolidWorks allows us to use an existing model and bring it into MapleSim,” said Bernardin. “If you have an existing design in SolidWorks, you can bring that in and add components, electric motors, or damping or hydraulic subsystems, and simulate the system and get a 3D visualization of how the SolidWorks model behaves with all of the components.”

Before the integration, the product drawing had to be put through analysis piece by piece. “In the past, we had to work through this manually. You would miss the opportunity to see the whole system together,” said Bernardin. “Now you can get going quickly in system-level modeling. We do this with all of the major CAD systems now. We want to make sure our tools are not islands, that they’re integrated with the tools our customers are using.”

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like