May 11, 2012

Automotive Tier 1 supplier Johnson Controls has up-leveled its automotive interiors design operation with the Teamcenter design platform from Siemens PLM Software. The company's Automotive Experience division is rolling out Siemens PLM software across its 200 plants worldwide.

"When we looked at the design of the seats and door panels Johnson Controls was working with, it was a hodgepodge of spreadsheets, prototypes, and paper templates," Steven Luby, president and CEO of Vistagy, a division of Siemens PLM, told Design News at the 2012 Siemens PLM Connection Americas Users Conference in Las Vegas. "They didn't really have software to manage this."

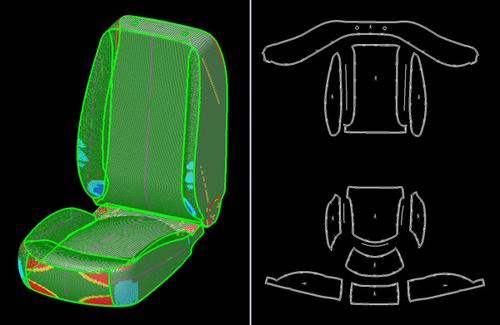

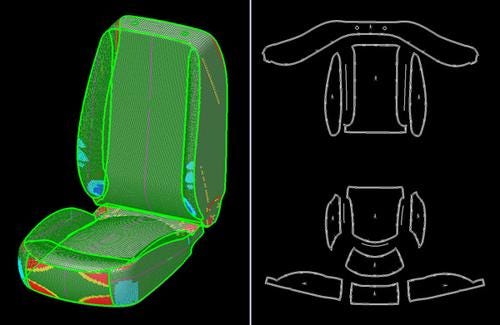

The seats were difficult to design with the existing tools, plus they offered little in help for improving efficiency and productivity. "In trying to design seats with all the different layers of material, it was incredibly painful for them," said Luby. "We looked at the problem and told them we could provide an environment where they could go to 3D."

The first thing Siemens did was to bring Johnson Controls design engineers into the process of setting up the system. "We started talking with them about pieces, and seams, and foam. We let the engineers define the system their way, with their materials," said Luby. "Now they have the visualization and documentation that allows them to bid on a seam in less than a day. It used to take them three weeks."

The bidding process is just one of a wide range of tools designed to improve Johnson Controls' design efficiency across the globe. Once the Siemens platform is fully implemented, all units will be integrated with uniform design tools. "We gave them productivity tools, and those tools are starting to transform what they're doing," said Luby. "You make a change and push a button, and all the manufacturing data updates, all the documentation updates, the BOM updates."

Sanjay Rishi, Johnson Controls' group vice president of information technology, said in a statement that the company was seeking a scalable and comprehensive PLM solution when it chose Siemens PLM.

The ultimate goal for Johnson Controls is to drive down costs while improving service and performance to its OEM customers. "The driver for Johnson Controls' adoption of Teamcenter was efficiency," said Robert Jones, senior vice president of industry at Siemens. "They needed their design system to be uniform from Detroit to India." Jones said that the improved design system makes Johnson Control's Automotive Experience division a better customer for its OEM customers. "They can do more innovation and take more products to market."

Related posts:

About the Author(s)

You May Also Like