The promises that come from big data are stalled when the information is hard to obtain and even harder to manage.

March 29, 2016

While the benefits of big-data analysis are touted across the product development world, companies are struggling to access useful data. Once the data is obtained, the further step of cleansing that data can prove even more difficult. Fifty-seven percent of manufacturers don’t have access to reliable product genealogy information, and 72% believe their product data is less than 80% accurate. These findings come from the research report Capitalizing on Big Data from Products, produced by Iyno Advisors for Siemens. The report notes that IT infrastructure makes it difficult to turn current data into usable information. Even so, select pioneers are making enormous strides in leveraging big-data analytics to improve product performance and enhance product-related decision making.

The problem is that the data resides in different areas of the organization and comes in a variety of incompatible forms. “Big data is disparate data, in varied formats, from different sources. Even high-volume data that is from a single source is pretty easy to handle in comparison,” Jeff Hill, senior advisor at Iyno Advisors, told Design News. “So an ideal big data solution would provide clean and coherent data across into all parts of the company's business.”

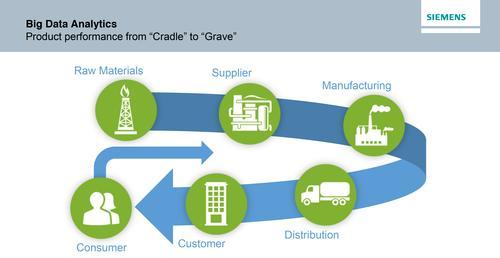

Getting clean data requires a strategy that moves on a clear path through each stage of the product-development process. “Data collection ought to start with product design, proceed to testing, manufacturing, distribution, and finally to the end-user to the customer's experience, use, and product end-of-life,” said Hill. “Putting all this in a context as ‘clean’ product data allows the company to pinpoint issues.”

Clean data that maps the path from design to customer use can become the evidence trail in tracking down problems with the product. “Using data, you can see whether a design or procurement decision might have led to a component that created problems in manufacturing or higher-than-normal repair requests,” said Hill. “Decisions made with timely and accurate product data across this broad spectrum speeds decisions that affect customer loyalty and brand reputation.”

Obtaining Big Data Is a Struggle

Effective analysis also needs data from outside the organization, whether from suppliers or customers. The report confirms that most companies struggle with data from outside the enterprise: from suppliers and from the field as products are in use. Most companies know they must improve product quality, customer satisfaction, and new product introduction time. However; for more than half of the respondents, data on genealogy, root causes, and supplier engineering changes takes weeks to obtain or is not available at all.

The data that is most difficult to obtain in usable form comes from specific areas. “Our research shows that the data most likely to be unavailable is genealogy data, which spans suppliers and customers," said Hill. "The next most commonly unavailable data is device direct data from use at customers, followed by risk or FMEA data which comes from design.”

In addition to difficulties in obtaining outside data, it can be difficult to get data from different departments within the organization. "Re-framing the possibilities from traditional analytics to cross-discipline big data is a challenge,”said Julie Fraser, principal at Iyno Advisors. “What many companies struggle with is aggregating and correlating data from different operational areas or applications within the organization, what is often called the silo effect.”

READ MORE ARTICLES ON BIG DATA:

Yet some electronics companies that harness big data analytics power are on a better track: respondents who improved their performance on four out of five business metrics, or Improvers, make up about a quarter of the survey response base. Improvers were two to 15 times more likely to see data from key business processes in minutes. These processes encompass:

R&D: design risk including failure mode effects analysis, engineering changes, both internal and from suppliers

Production: yield, manufacturing test log and machine data

Supply chain: genealogy

Customer in-use: where shipped, return materials authorizations, field and device direct data.

The ultimate goal of big-data analysis is simple –- to focus on opportunities to serve customers better. “Big data opportunities are everywhere, but in this research, we found that those companies that were most likely to use big data effectively were those who were able to focus on the things the customer cares about: customer satisfaction and service," said Hill.

[image via Siemens]

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like