CFD, FEA, and simulation software have accelerated time-to-market in product development and put the CAE analysis “knobs and levers” in the hands of design engineers.

February 8, 2016

There’s nothing new about testing and analyzing product prototypes virtually. Finite element analysis (FEA) and computational fluid dynamics (CFD), collectively CAE, have been around for years. Likewise with simulation programs that show a product in motion and under use. These tools have belonged to the province of trained expert users.

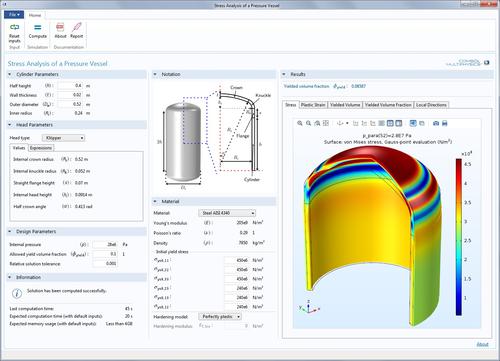

The Application Builder allows COMSOL Multiphysics software users to build an intuitive interface around their model that can be run by anyone, even those without prior simulation experience.

(Source: COMSOL)

But now they are being put in the hands of design engineers. And they have also become collaborative, letting design teams work with CAE experts earlier in the design and development process in order to collapse the time it takes to arrive at a final product. CAE and simulation tools are getting integrated into CAD and manufacturability analysis in order to accelerate the move from product conception to delivery even further. The goal is to run analysis and simulation simultaneously with design rather than in sequence.

Speeding up time-to-market may be the underlying goal of these developments, but there is also an eye toward reducing development costs. When you move CAE to earlier points in the design process, a virtual model can be tested earlier and modifications can be made with greater ease, while the design team doesn’t have to physically build and test each new design, thus avoiding costs.

Collaboration Tools Offer Simultaneous Design and Engineering

The typical, time-consuming process for testing a product was to submit the CAD drawings to a series of experts and wait for their diagnoses. “Traditionally, you had a design team sending drawings to the analysis team, the structural team, the fluid dynamics team. There has not been much integrated collaboration during this process,” Bjorn Sjodin, vice president of product management at multiphysics modeling software company COMSOL, told Design News. “It’s usually a sequence of passing files around. Now there is an attempt to get away from that way of doing things.”

[Learn more design hardware & software trends and developments at Pacific Design & Manufacturing, Feb. 9-11, at the Anaheim Convention Center.]

Various CAE work can go on simultaneously to bring efficiency, but it also brings multi-aspect analyses. “Time-to-market is one of the more important reasons for collaboration. Also, there is a move to get more realistic simulations,” Sjodin said. “If you look at [your product] from just a structure viewpoint, you might lose out on the heat aspects or the acoustic aspects, or the fluid dynamics. If your competitor takes those into account [with its product] and you don’t, you lose.”

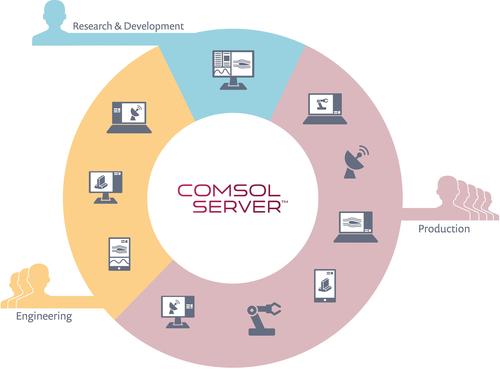

COMSOL created a collaboration tool to facilitate simultaneous development work. “There are different types of web tools for collaboration, and there are many companies offering web tools in many different flavors. We decided to provide COMSOL Server,” Sjodin said, describing it as a web-based simulation app and a pared-down version of its full multiphysics engine.

This COMSOL Multiphysics simulation app analyzes whether a pressure vessel with a given geometry will be able to sustain an applied internal pressure without exceeding a certain volume fraction of the material which has exceeded the yield limit. Geometric parameters and materials may be changed to investigate different vessel designs.

(Source: COMSOL)

The collaboration tool cuts away at the traditional sequential moves. “The guy putting together the original simulation may need to send it to an expert in another field. The COMSOL Server app allows him to share the simulation with someone with more expertise, say, in advanced manufacturing,” Sjodin said. “He can share just what he needs. The outcome sought may be just temperature or stress.”

READ MORE ARTICLES ON SIMULATION AND ANALYSIS:

The design team may only need to ask whether the design would work. Then the product may need to be changed in order to reach functionality. The sharing can let the expert make adjustments to the product rather than just offer analysis. “The collaboration allows the user to interact with the models and play around with them even if the user doesn’t know about simulation,” Sjodin said.

Advances in computer processing speed and that ability to share very large files have helped make collaboration possible. Plus, design tools now allow design engineers to highlight only the part of the design that’s in question. “In the past, the design would have a few hundred parameters and the expert wouldn’t know what parameters were relevant,” Sjodin said. “Now you can highlight to the parameters. It brings the sharing down to a manageable interface.”

About the Author(s)

You May Also Like